Detailed Product Description

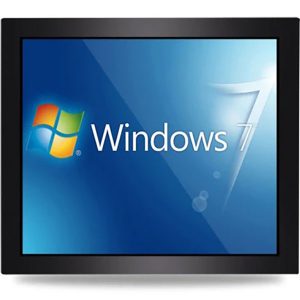

Ip65 industrial monitor

Ip65 industrial monitor made from our industrial monitor manufacturer are high quality, we provide ip65 industrial monitor wholesale and customize, all the ip65 industrial monitor made by us accord high qualit control and testing system, welcome to our website www.industrialmonitormanufacturer.com, here is the detailed introduction to ip65 industrial monitor.

An IP65 industrial monitor is a type of display specifically designed for use in industrial environments. The "IP" in IP65 stands for "Ingress Protection," and it indicates the monitor's level of protection against solid particles (first digit) and liquids (second digit).

In the case of an IP65 industrial monitor: The first digit "6" signifies that the monitor is dust-tight, providing complete protection against the ingress of dust or other solid particles.

The second digit "5" indicates that the monitor is protected against water jets from all directions. This means it can withstand low-pressure water jets or splashes, making it suitable for use in environments where it may be exposed to water.

Overall, an IP65 industrial monitor is well-suited for applications where there's a need for a rugged and durable display that can withstand harsh industrial conditions, including potential exposure to dust and water. It's commonly used in manufacturing facilities, warehouses, outdoor installations, and other environments where standard monitors might not be suitable. |

|

|

|

Ip65 industrial monitor specifications

Specifications of ip65 industrial monitor | Detailed description of ip65 industrial monitor specifications

|

| Ip65 industrial monitor | 12.1″ Color TFT IP65 front touchscreen Monitor |

| Model Name | AXD-12OPIPN1P2-T2 |

| Active Display Area (mm) | 246.0 (H) x 184.5 (V) |

| Pixel Pitch (mm) | 0.297 (H) x 0.297 (V) |

| Resolution (Pixel) | 1024X768 |

| Brightness (CD/m^2) | 400cd/m^2 |

| Contrast Ratio | 700:1 |

| Viewing Angle (CR >=10) | 160/140 |

| Power consumption | 10.3 W typical, normal operation |

| Touch Screen |

|

| Type | Flat capacitive touchscreen USB |

| Durability | 50 Million touches with 10 point multi-touch |

| OSD Control | On the back side |

| I/O Connectors | 1x12v,1XVGA,DVI-D |

| Power Input | AC 100~240V,Universal,±10% ; AC/DC 12V4A |

| Mechanical Specifications |

|

| Construction | Aluminum Frame with rugged powered housing |

| Dimensions | 315.6x 254.6x 54.8(mm) |

| Mounting | Up-down, Left-right panelmount screws fixing holes ,VESA 75×75(100×100) |

| Power source | AC 100~240V/ 12V DC |

| Environment Specifications |

|

| Operating Temperature | -20~70ºC |

| Storage Temperature | -30~80ºC |

| Rating | Facilitate installation of the demolition, solid portfolio |

| Ordering Information | 12.1″ panelmount Monitor 1024X768 hd 400nits with HD VGA input and power adapter |

Introducing the AXD-12OPIPN1P2-T2, a high-performance IP65 industrial monitor designed to excel in demanding environments. This rugged 12.1-inch Color TFT touchscreen monitor is engineered for reliability and durability.

Key Specifications for this ip65 industrial monitor:

Active Display Area (mm): 246.0 (H) x 184.5 (V)

Pixel Pitch (mm): 0.297 (H) x 0.297 (V)

Resolution (Pixel): 1024X768

Brightness (CD/m^2): 400cd/m^2

Contrast Ratio: 700:1

Viewing Angle (CR >=10): 160/140

Touchscreen of ip65 indusrial monitor:

Type: Flat capacitive touchscreen USB

Durability: 50 Million touches with 10 point multi-touch

Power Consumption:

Typical: 10.3 W in normal operation

I/O Connectors for ip65 industrial monitor:

1x 12v

1x VGA

1x DVI-D

Power Input of ip65 industrial monitor:

AC: 100~240V, Universal, ±10%

AC/DC: 12V4A

Mechanical Specifications of ip65 industrial monitor:

Construction: Aluminum Frame with rugged powered housing

Dimensions: 315.6 x 254.6 x 54.8 (mm)

Mounting: Up-down, Left-right panel mount screws fixing holes, VESA 75×75(100×100)

Power Source: AC 100~240V/ 12V DC

Environment Specifications of ip65 industrial monitor:

Operating Temperature: -20~70ºC

Storage Temperature: -30~80ºC

Rating: Facilitates easy installation and removal, ensuring a robust setup.

Ordering Information:12.1″ panel mount Monitor, 1024X768 HD, 400 nits with HD VGA input and power adapter.

Experience unparalleled performance and reliability with our IP65 industrial monitor, designed to meet the rigorous demands of industrial applications. With its impressive specifications and robust construction, it is the perfect choice for environments that require a rugged and dependable display solution.

Detailed introduction to ip65 industrial monitor

Specifications of ip65 industrial monitor | Features of ip65 industrial monitor

| Classification of ip65 industrial monitor |

Applications of ip65 industrial monitor

| Technology of ip65 industrial monitor

| Process of ip65 industrial monitor

|

ip65 Industrial monitor customization | Advantages of ip65 industrial monitor | Future of ip65 industrial monitor |

Specifications of industrial monitor

common specifications for an IP65 industrial monitor:

- Ingress Protection Rating: IP65

- Display Type: TFT (Thin Film Transistor) or LCD (Liquid Crystal Display)

- Screen Size: Typically available in various sizes (e.g., 12.1", 15", 17", 19", etc.)

- Active Display Area (mm): Dimensions of the visible screen area

- Resolution (Pixel): The number of pixels horizontally and vertically (e.g., 1024x768)

- Brightness (CD/m^2): Luminance of the display screen in candela per square meter

- Contrast Ratio: Ratio of the brightest to the darkest part of the display

- Viewing Angle (CR >=10): The maximum angle at which the display can be viewed clearly

- Touchscreen Type: Resistive, Capacitive, Infrared, etc.

- Touchscreen Durability: Number of touches and type of touch technology (e.g., capacitive, resistive)

- Power Consumption: Typically in watts during normal operation

- Input Connectors: VGA, DVI-D, HDMI, etc.

- Power Input: Voltage range and current specifications (e.g., AC 100~240V, 12V DC)

- Construction: Material and design of the monitor frame or housing

- Dimensions (mm): Width, height, and depth of the monitor

- Mounting Options: Panel mount, VESA mount, etc.

- Operating Temperature Range: Minimum and maximum temperatures at which the monitor can operate

- Storage Temperature Range: Minimum and maximum temperatures for safe storage

- Rating: Information regarding the monitor's installation and robustness

- Additional Features: Any extra functionalities or features specific to the monitor model

These specifications provide essential information about an IP65 industrial monitor and help users determine if it's suitable for their specific application. Keep in mind that actual specifications may vary depending on the manufacturer and model.

Features of ip65 industrial monitor

Some common features of ip65 industrial monitors:

| Feature | Description |

|---|

| Ingress Protection (IP65) | Complete protection against dust and low-pressure water jets |

| Rugged Construction | Built to withstand harsh industrial conditions |

| Display Type (TFT or LCD) | Utilizes advanced display technology for high-quality visuals |

| Various Screen Sizes | Available in different sizes to accommodate specific applications |

| High Resolution | Provides clear and sharp images, often 1024x768 or higher |

| High Brightness | Enhanced visibility, especially in environments with high ambient light |

| Wide Viewing Angle | Allows for clear visibility from different angles |

| Touchscreen Technology | Capacitive or resistive touchscreens for intuitive user interaction |

| Multi-Touch Support | Some models support multi-touch gestures, allowing versatile input methods |

| Durability | Built to withstand frequent and rigorous use |

| Anti-Glare or Anti-Reflective Coating | Reduces glare and reflections on the screen, enhancing visibility |

| Shock and Vibration Resistance | Designed to handle vibrations and shocks in industrial environments |

| Wide Temperature Range | Capable of operating in extreme temperature conditions |

| Versatile Mounting Options | Supports various mounting methods, such as panel mounting, VESA mounting, etc. |

| Multiple Input Connectors | Includes VGA, DVI-D, HDMI, and other ports for versatile connectivity |

| Power Efficiency | Designed for energy efficiency to minimize power consumption |

| OSD (On-Screen Display) Control | Allows users to adjust settings directly on the monitor |

| Compatibility | Compatible with various industrial equipment and systems |

| Customization Options | Some models offer customization options to meet specific application requirements |

| Facilitated Installation | Designed for easy installation and maintenance |

|

Here are the common features of an IP65 industrial monitor: Ingress Protection (IP65): Offers complete protection against dust and low-pressure water jets, making it suitable for harsh industrial environments. Rugged Construction: Designed to withstand challenging conditions commonly found in industrial settings. TFT or LCD Display: Utilizes advanced display technology for high-quality visuals. Various Screen Sizes: Available in different sizes to accommodate specific application requirements (e.g., 12.1", 15", 17", 19", etc.). High Resolution: Provides clear and sharp images, often with a resolution of 1024x768 or higher. High Brightness: Offers enhanced visibility, especially in environments with high ambient light. Wide Viewing Angle: Allows for clear visibility from different angles, ensuring optimal viewing for operators. Touchscreen Technology: Capacitive or resistive touchscreens for intuitive user interaction. Multi-Touch Support: Some models support multi-touch gestures, allowing for versatile input methods. Durability: Built to withstand frequent and rigorous use, ensuring longevity and reliability. Anti-Glare or Anti-Reflective Coating: Reduces glare and reflections on the screen, enhancing visibility. Shock and Vibration Resistance: Designed to handle vibrations and shocks that may occur in industrial environments. Wide Temperature Range: Capable of operating within a broad temperature range, ensuring performance in extreme conditions. Versatile Mounting Options: Supports various mounting methods, such as panel mounting, VESA mounting, etc. Multiple Input Connectors: Includes VGA, DVI-D, HDMI, and other ports for versatile connectivity. Power Efficiency: Designed for energy efficiency to minimize power consumption. OSD (On-Screen Display) Control: Allows users to adjust settings directly on the monitor. Compatibility: Compatible with various industrial equipment and systems for seamless integration. Customization Options: Some models may offer customization options to meet specific application requirements. Facilitated Installation: Designed for easy installation and maintenance.

These features collectively make an IP65 industrial monitor a robust and reliable solution for use in demanding industrial environments. Keep in mind that actual features may vary depending on the specific make and model of the monitor.

|

Classification of ip65 industrial monitor

IP65 industrial monitors can be classified based on various criteria. Here are some common classification categories: Screen Size: - Small (e.g., 7" to 10")

- Medium (e.g., 12" to 17")

- Large (e.g., 19" and above)

Touchscreen Technology: - Capacitive

- Resistive

- Infrared

- Others

Mounting Options: - Panel Mount

- VESA Mount

- Rack Mount

- Open Frame

Input Connectors: Additional Features: - Multi-Touch Support

- Sunlight Readability

- Anti-Glare Coating

- High Brightness

- Anti-Vibration

Durability Level: Operating Environment: Application Focus: - Manufacturing

- Transportation

- Healthcare

- Utilities

- Military/Defense

- Others

Customization Options: - Custom Bezels

- Custom Inputs

- Specialized Enclosures

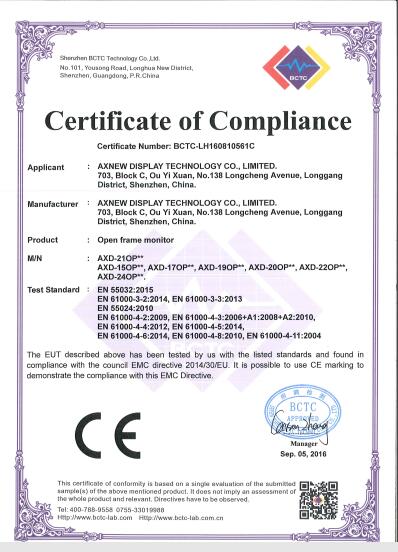

Industry Standards: - Compliance with specific industry standards or certifications (e.g., NEMA, UL, CE)

Operating System Compatibility: - Compatibility with various operating systems (e.g., Windows, Linux)

Connectivity Options: Power Input Options: - AC

- DC

- PoE (Power over Ethernet)

Specialized Applications: - Marine Grade Monitors

- Hazardous Location Monitors (e.g., Class 1 Division 2)

Integrated Features: - Built-in Speakers

- USB Ports

- Protective Films (e.g., Tempered Glass)

Brand or Manufacturer: - Different manufacturers may offer varying features and specifications for their IP65 industrial monitors.

These classifications help users identify and choose the specific IP65 industrial monitor that best fits their application and environment. Keep in mind that the actual available options may vary depending on the manufacturer and model. |

|

Applications of ip65 industrial monitor

IP65 industrial monitors find a wide range of applications across various industries due to their rugged and durable design. Here are some common applications:

Manufacturing and Production Lines:

- Used for monitoring and controlling machinery and processes in manufacturing facilities.

Food and Beverage Industry:

- Employed in food processing plants to withstand washdowns and maintain hygiene standards.

Automotive Industry:

- Used in assembly lines and automotive plants to monitor production processes.

Warehousing and Logistics:

- Utilized for inventory management, order processing, and tracking shipments.

Medical and Healthcare:

- Found in hospitals and healthcare facilities for patient monitoring and medical equipment control.

Oil and Gas Industry:

- Used in harsh environments for monitoring drilling operations and equipment.

Mining Industry:

- Installed in mining operations for monitoring equipment status and control.

Transportation and Logistics:

- Employed in control rooms and vehicle terminals for monitoring transportation operations.

Outdoor and Harsh Environments:

- Used in outdoor applications where exposure to elements like rain, dust, or extreme temperatures is a concern.

Marine and Maritime Applications:

- Installed in marine vessels for navigation, control systems, and monitoring equipment.

Aerospace Industry:

- Used in aerospace manufacturing and testing facilities.

Chemical and Pharmaceutical Industry:

- Employed in facilities where resistance to chemicals and rigorous cleaning processes is essential.

Utilities and Power Generation:

- Used for monitoring and controlling equipment in power plants and utility facilities.

Military and Defense:

- Deployed in military vehicles, command centers, and field operations for reliable display solutions.

Cleanrooms and Controlled Environments:

- Installed in environments where maintaining cleanliness and sterility is critical.

Entertainment and Theme Parks:

- Used for interactive displays, ride control systems, and guest information kiosks.

Environmental Monitoring and Control:

- Employed in applications such as weather stations and environmental monitoring systems.

Construction and Heavy Equipment:

- Used in construction sites to monitor equipment performance and processes.

Pharmaceutical Manufacturing:

- Found in pharmaceutical production lines for process monitoring and control.

Water Treatment and Wastewater Management:

- Utilized in water treatment plants for monitoring and controlling treatment processes.

These are just some of the many applications of IP65 industrial monitors. Their ruggedness and ability to withstand challenging environments make them versatile solutions for a wide range of industries and settings.

|

|

Technology of ip65 industrial monitorThe technology of an IP65 industrial monitor involves a combination of advanced components and engineering techniques to ensure its durability, functionality, and performance in harsh industrial environments. Here are the key technological aspects: Ingress Protection (IP) Rating: The IP rating indicates the monitor's level of protection against solid particles (first digit) and liquids (second digit). An IP65 industrial monitor is specifically designed to be dust-tight and able to withstand low-pressure water jets from all directions. Ruggedized Design: The monitor is built with robust materials and construction methods to withstand vibrations, shocks, and other physical stresses commonly encountered in industrial settings. This includes reinforced frames, rugged enclosures, and strengthened housing. High-Quality Display Technology: Industrial monitors often utilize TFT (Thin Film Transistor) or LCD (Liquid Crystal Display) technology for high-resolution, high-contrast, and high-brightness screens. This ensures clear and sharp visuals even in demanding environments. Touchscreen Technology: Many industrial monitors incorporate touchscreen functionality, which can be either resistive or capacitive. These technologies allow for intuitive and interactive user interfaces, enabling operators to interact directly with the monitor. Anti-Glare and Anti-Reflective Coating: To enhance visibility, industrial monitors may be equipped with anti-glare or anti-reflective coatings. These coatings reduce reflections and minimize glare from ambient light sources. Wide Temperature Range Operation: Industrial monitors are designed to operate within a broad temperature range, ensuring functionality in extreme temperature conditions, whether in hot foundries or cold storage facilities. Vibration and Shock Resistance: These monitors are engineered to resist and absorb shocks and vibrations, common in industrial environments where heavy machinery or vehicles are in operation. EMI/RFI Shielding: Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) shielding is implemented to protect against electronic interference from surrounding equipment and machinery. IP65-Compliant Connectors and Seals: Input/output connectors are designed to be sealed and IP65-compliant to prevent the ingress of dust and water, maintaining the integrity of the monitor's internal components. OSD (On-Screen Display) Controls: Many industrial monitors feature OSD controls for convenient adjustments to settings such as brightness, contrast, color, and more. Customization Options: Depending on the manufacturer, industrial monitors may offer customization options to meet specific application requirements, such as custom bezels or specialized inputs. Durability Testing: Industrial monitors undergo rigorous testing to ensure they meet industry standards for durability, reliability, and performance. This may include tests for vibration resistance, temperature tolerance, and more.

These technological features collectively make an IP65 industrial monitor a reliable and robust solution for use in challenging industrial environments. Keep in mind that the specific technologies incorporated may vary depending on the manufacturer and model. | Process of ip65 industrial monitorThe process of manufacturing an IP65 industrial monitor involves several stages, from design and component selection to assembly and testing. Here is an overview of the typical steps involved: Design and Planning: - Engineers and designers create a detailed plan for the industrial monitor, including specifications, features, and dimensions. They consider factors such as environmental conditions, screen size, touchscreen technology, and connectivity options.

Component Selection: - High-quality components are selected for the monitor, including TFT or LCD panels, touchscreen sensors, ruggedized frames, connectors, and other electronic elements. Special attention is given to components that meet IP65 protection standards.

Assembly of Electronic Components: - The electronic components, including the display panel, control boards, touch panel, and power supply, are assembled onto the monitor's PCB (Printed Circuit Board).

Enclosure and Housing Fabrication: - The monitor's enclosure and housing are typically made from rugged materials such as aluminum or stainless steel. These materials provide durability and protection against harsh industrial environments.

Sealing and Gasketing: - Gaskets, seals, and adhesives are used to seal critical areas of the monitor to ensure its IP65 rating. This prevents the ingress of dust and water into sensitive components.

Integration of Touchscreen Technology: - If the monitor includes touchscreen functionality, the appropriate technology (capacitive, resistive, etc.) is integrated into the display assembly.

Testing and Quality Control: - The assembled monitor undergoes rigorous testing to ensure it meets IP65 standards and other performance criteria. This includes tests for dust resistance, water resistance, shock resistance, temperature tolerance, and more.

Installation of Input/Output Connectors: - Input/output connectors, such as VGA, DVI-D, HDMI, and power connectors, are installed on the monitor. These connectors are designed to be sealed and comply with IP65 standards.

OSD Control Integration: - On-Screen Display (OSD) controls are integrated into the monitor, allowing users to adjust settings like brightness, contrast, and color.

Final Assembly and Inspection: - All components are assembled into the final monitor unit. A thorough inspection is conducted to ensure all parts are correctly assembled and functioning properly.

Customization (Optional): - Depending on customer requirements, customization options like specialized bezels, custom inputs, or additional features may be incorporated.

Packaging and Shipping: - The finished monitors are carefully packaged to protect them during transit and are then shipped to distributors or end-users.

Throughout the process, manufacturers adhere to industry standards and quality control measures to ensure that the IP65 industrial monitors meet or exceed performance expectations in demanding industrial environments. |

ip65 Industrial monitor customization

Customizing an IP65 industrial monitor involves tailoring specific features and functionalities to meet the unique requirements of a particular application or industry. Here are the steps typically involved in the customization process:

Consultation and Requirements Gathering:

- The customization process begins with a thorough consultation between the manufacturer and the client. During this phase, the client outlines their specific needs, such as screen size, touchscreen technology, connectivity options, additional features, and any industry-specific requirements.

Component Selection and Integration:

- Based on the client's requirements, the manufacturer selects and integrates specific components, such as display panels, touchscreens, connectors, and other electronic elements. These components are chosen to meet the desired IP65 protection standards.

Enclosure and Housing Customization:

- The enclosure and housing of the monitor can be customized to suit the client's preferences or specific environmental conditions. This may include selecting different materials (e.g., stainless steel, aluminum) or modifying the design to accommodate specific mounting options.

Touchscreen Technology Selection:

- The choice of touchscreen technology (e.g., capacitive, resistive) can be tailored to match the intended user interaction and environmental conditions.

Specialized Features and Connectivity:

- Depending on the application, specialized features like sunlight readability, anti-vibration capabilities, or specific connectivity options (e.g., additional ports, wireless capabilities) can be integrated.

OSD Control Customization:

- The On-Screen Display (OSD) controls can be tailored to include specific settings and adjustments that are relevant to the client's application.

Custom Bezels and Mounting Options:

- Custom bezels can be designed to match the aesthetics or functionality requirements of the application. Additionally, specific mounting options (e.g., VESA, panel mount) can be incorporated.

Testing and Quality Assurance:

- The customized monitor undergoes thorough testing to ensure that all customizations meet performance standards and that the IP65 rating is maintained.

Prototype and Validation:

- A prototype of the customized monitor may be provided for client validation and testing in their specific environment.

Production and Delivery:

- Once the customized monitor design is approved, it moves into production. The finished product is then carefully packaged and delivered to the client.

Documentation and Support:

- The manufacturer provides documentation detailing the specifications and features of the customized monitor. Ongoing support and maintenance may also be offered.

Customizing an IP65 industrial monitor ensures that it meets the precise needs of the application, providing a reliable and tailored solution for demanding industrial environments.

Advantages of ip65 industrial monitor

| IP65 industrial monitors offer several advantages that make them well-suited for use in demanding industrial environments. Here are some key advantages: Protection Against Dust and Water: - IP65 industrial monitors are designed to be dust-tight and can withstand low-pressure water jets from all directions. This makes them highly resilient in environments where dust and water exposure are common.

Rugged and Durable Design: - These monitors are built with robust materials and construction methods to withstand vibrations, shocks, and physical stresses commonly encountered in industrial settings. This ensures longevity and reliable performance.

Suitable for Harsh Environments: - They can operate effectively in a wide range of harsh conditions, including manufacturing facilities, outdoor installations, warehouses, and locations where standard monitors might not be suitable.

Reduced Downtime and Maintenance Costs: - Their durability and resistance to environmental elements reduce the likelihood of damage or malfunction, leading to fewer instances of downtime and lower maintenance costs.

Wide Operating Temperature Range: - IP65 industrial monitors are designed to operate within a broad temperature range, ensuring functionality in extreme hot or cold environments.

Enhanced Visibility and Readability: - Many models come with features like high brightness and anti-glare or anti-reflective coatings, which improve visibility even in environments with high ambient light.

Touchscreen Functionality: - They often include touchscreen technology, allowing for intuitive user interaction without the need for additional input devices.

Versatile Mounting Options: - IP65 monitors can be panel-mounted, VESA-mounted, or integrated into custom enclosures, providing flexibility in how they are installed and used in various applications.

Customization Options: - They can be customized to meet specific application requirements, including screen size, touchscreen technology, connectors, and additional features.

Compliance with Industry Standards: - Many IP65 industrial monitors are designed to meet industry-specific standards, ensuring they can be seamlessly integrated into existing systems and equipment.

Protection Against Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI): - They are often equipped with shielding to protect against electronic interference from surrounding equipment and machinery.

Long-Term Cost Savings: - While the initial investment may be higher than standard monitors, the reduced need for replacements and maintenance over time can lead to cost savings in the long run.

Safety and Reliability: - The rugged design and resistance to environmental factors ensure that these monitors operate reliably and safely in critical industrial applications.

These advantages collectively make IP65 industrial monitors a reliable and cost-effective solution for industries where durability and functionality in harsh environments are paramount. |

Future of ip65 industrial monitor

The future of IP65 industrial monitors is likely to see several advancements and trends that will further enhance their capabilities and adaptability to evolving industrial needs. Here are some potential developments:

Integration of Advanced Technologies:

- Continued integration of cutting-edge technologies such as edge computing, IoT (Internet of Things), and AI (Artificial Intelligence) will enable IP65 monitors to play a more central role in data processing, analysis, and automation within industrial environments.

Improved Touchscreen Technology:

- Advancements in touchscreen technology will lead to more responsive and durable screens, potentially incorporating features like multi-touch gestures, gesture recognition, and haptic feedback for enhanced user interaction.

Higher Resolution and Enhanced Visuals:

- Higher-resolution displays with improved color accuracy and contrast ratios will provide even clearer and more detailed visuals for critical applications, allowing for better decision-making and analysis.

Augmented Reality (AR) and Virtual Reality (VR) Integration:

- AR and VR technologies may be integrated into IP65 industrial monitors to enhance training, maintenance, and remote assistance in industrial settings.

Increased Connectivity Options:

- Greater connectivity options, including support for 5G, enhanced Wi-Fi capabilities, and more advanced communication protocols, will facilitate seamless integration into Industry 4.0 environments.

Enhanced Environmental Resistance:

- Future IP65 monitors may feature even higher levels of environmental resistance, potentially achieving higher IP ratings for even more extreme conditions.

Energy Efficiency and Sustainability:

- Efforts to improve energy efficiency and reduce power consumption will likely be incorporated, aligning with global sustainability goals and providing cost savings for users.

Customization for Specific Industries:

- Manufacturers may offer more specialized models tailored to specific industries, incorporating features and capabilities optimized for the unique requirements of each sector.

Incorporation of Advanced Materials:

- Advancements in materials science may lead to the development of even more durable and lightweight components, further enhancing the ruggedness of IP65 monitors.

Advanced Human-Machine Interfaces (HMIs):

- Future monitors may offer more sophisticated HMIs with intuitive user interfaces, advanced gesture controls, and voice recognition for more seamless interaction.

Predictive Maintenance Capabilities:

- Integration with predictive maintenance algorithms and systems will enable IP65 monitors to provide real-time feedback on the condition of machinery and equipment, helping to prevent unexpected failures.

Compliance with Emerging Standards:

- Adherence to evolving industry and regulatory standards will ensure that IP65 industrial monitors remain compatible with the latest technologies and systems.

Overall, the future of IP65 industrial monitors is likely to be characterized by a continued focus on innovation, adaptability, and integration into increasingly sophisticated industrial environments. These advancements will further solidify their role as critical components in modern industrial processes.

(FAQs) about ip65 industrial monitors

What is an IP65 industrial monitor?

- An IP65 industrial monitor is a ruggedized display designed to operate reliably in harsh industrial environments. The "IP" in IP65 stands for "Ingress Protection," indicating the monitor's level of protection against solid particles and liquids.

What does IP65 rating mean?

- The IP65 rating signifies that the monitor is dust-tight (6) and protected against water jets from all directions (5). It can withstand low-pressure water jets or splashes, making it suitable for use in environments exposed to water.

Where are IP65 industrial monitors commonly used?

- They are used in a wide range of industrial applications, including manufacturing facilities, warehouses, outdoor installations, food processing plants, healthcare settings, transportation, and more.

What are the key features of an IP65 industrial monitor?

- Key features may include dust and water resistance, ruggedized construction, touchscreen functionality, high brightness displays, wide temperature range operation, and versatile mounting options.

Can IP65 industrial monitors be used outdoors?

- Yes, IP65 industrial monitors are designed to withstand outdoor environments where exposure to dust and water is likely.

What is the difference between resistive and capacitive touchscreens in IP65 monitors?

- Resistive touchscreens are pressure-sensitive and can be activated with a stylus or any object. Capacitive touchscreens respond to the touch of a conductive material, like a finger, providing a more intuitive interface.

Can IP65 monitors be customized for specific applications?

- Yes, many manufacturers offer customization options, allowing customers to tailor the monitor's features, such as screen size, touchscreen technology, connectors, and additional functionalities.

Are IP65 monitors compatible with industrial automation systems?

- Yes, IP65 industrial monitors are designed to seamlessly integrate with various industrial automation systems, including PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems.

Do IP65 monitors come in different screen sizes?

- Yes, they are available in various screen sizes to accommodate different applications and user preferences.

What is the operating temperature range of an IP65 industrial monitor?

- The operating temperature range typically varies depending on the specific model, but many IP65 monitors are designed to operate within a range of -20°C to 70°C.

Can IP65 monitors be used in hazardous environments?

- Some models may be designed for use in hazardous locations and carry specific certifications, such as Class 1 Division 2 (C1D2) for potentially explosive atmospheres.

Are IP65 monitors compatible with industrial software applications?

- Yes, IP65 monitors are designed to run a wide range of industrial software applications, including HMI (Human-Machine Interface) software and SCADA systems.

Do IP65 monitors have built-in speakers?

- Some models may include built-in speakers for audio output, but this feature may vary depending on the specific model.

Can IP65 monitors be panel-mounted or VESA-mounted?

- Yes, they typically offer versatile mounting options, including panel mounting, VESA mounting, and other customizable mounting solutions.

Do IP65 monitors support multi-touch gestures?

- Some models may support multi-touch gestures, allowing for more versatile and intuitive user interaction.

Are IP65 monitors compatible with industrial controllers and PLCs?

- Yes, they are designed to integrate seamlessly with various industrial controllers and programmable logic controllers (PLCs) commonly used in industrial automation.

Can IP65 monitors be used in cleanroom environments?

- Yes, depending on the specific model and its certifications, some IP65 monitors can be used in cleanroom environments where maintaining cleanliness and sterility is crucial.

What type of connectors do IP65 monitors have?

- They typically feature a range of input/output connectors, including VGA, DVI-D, HDMI, and other ports for versatile connectivity.

Do IP65 monitors require special installation considerations?

- Installation considerations may vary depending on the specific model and application, but they are generally designed for easy installation and maintenance.

What are the long-term cost benefits of using IP65 industrial monitors?

- While the initial investment may be higher than standard monitors, the reduced need for replacements and maintenance in demanding industrial environments can lead to cost savings in the long run.