Features of panel mount industrial monitorThe features of a panel-mount industrial monitor may vary depending on the specific model and manufacturer. However, here are some common features that are often associated with panel-mount industrial monitors: Panel Mounting: - Designed for secure mounting directly onto a control panel, machine, or enclosure, providing a flush and integrated appearance.

Rugged Construction: - Built with a rugged design to withstand harsh industrial environments, including resistance to shock, vibration, dust, and moisture.

Durability: - Engineered for long-term use in industrial settings, ensuring durability and reliability in challenging conditions.

Touchscreen Options: - Many panel-mount industrial monitors come with touchscreen options, providing interactive capabilities for control panels and human-machine interface (HMI) systems.

High Brightness and Contrast: - Typically features high brightness levels and contrast ratios to ensure clear visibility in different lighting conditions within industrial environments.

Customization Options: - Offers customization options to meet specific requirements, including various sizes, resolutions, touchscreen technologies, and connectivity options.

Multiple Connectivity Options: - Equipped with a range of connectivity options such as VGA, DVI, HDMI, USB, and serial ports to ensure compatibility with industrial equipment and systems.

Panel Mounting Compatibility: - Supports various panel mounting methods to facilitate easy installation on control panels or enclosures.

IP Ratings: - Some panel-mount industrial monitors come with Ingress Protection (IP) ratings, indicating resistance to dust and water. This is important in environments where exposure to these elements is common.

Wide Temperature Range: - Capable of operating over a wide temperature range, making them suitable for environments with temperature variations.

Application-Specific Designs: - Tailored for specific applications such as manufacturing, process control, automation, and other industrial processes.

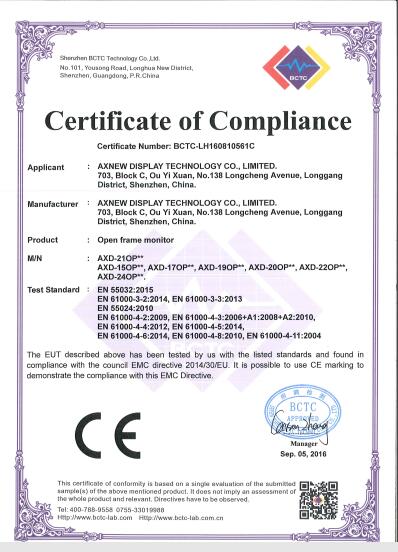

Compliance with Industry Standards: - Often complies with industry standards and certifications to ensure safety, reliability, and performance.

Long Product Lifecycle: - Designed with a focus on longevity, providing a longer product lifecycle compared to consumer-grade monitors.

High Resolution: - Offers high-resolution displays for crisp and detailed visuals, essential for monitoring and controlling industrial processes.

Compact Design: - Compact form factor to fit seamlessly into control panels or limited-space industrial environments.

Anti-Glare Coating: - Some models may feature anti-glare coatings to improve visibility and reduce reflections in brightly lit environments.

These features collectively make panel-mount industrial monitors well-suited for applications in industrial automation, process control, and other scenarios where a robust and integrated display solution is required. | Advantages of panel mount industrial monitorPanel-mount industrial monitors offer several advantages, making them a preferred choice for various industrial applications. Here are some key advantages: Seamless Integration: - The primary advantage is the seamless integration of panel-mount monitors into control panels, machines, or enclosures, providing a clean and integrated appearance.

Space Efficiency: - Panel-mount monitors save space by directly mounting onto control panels, eliminating the need for additional external enclosures.

Rugged Construction: - Built with a rugged design, these monitors are durable and can withstand harsh industrial environments, including exposure to shock, vibration, dust, and moisture.

Durability and Reliability: - Engineered for long-term use, panel-mount industrial monitors are reliable and durable, ensuring continuous operation in demanding industrial settings.

Interactive Touchscreen Options: - Many panel-mount monitors come with touchscreen options, allowing for interactive control panels and human-machine interface (HMI) systems, enhancing user interaction.

Customization Options: - Offers customization options for various specifications, including size, resolution, touchscreen technology, and connectivity, catering to specific industrial requirements.

Wide Temperature Range: - Capable of operating over a wide temperature range, making them suitable for industrial environments with varying temperature conditions.

IP Ratings for Environmental Protection: - Some models come with Ingress Protection (IP) ratings, indicating resistance to dust and water. This is crucial in environments where exposure to these elements is common.

High Brightness and Contrast: - Typically features high brightness levels and contrast ratios, ensuring clear visibility in different lighting conditions within industrial settings.

Application-Specific Designs: - Tailored for specific industrial applications such as manufacturing, process control, automation, and other scenarios where an integrated display is required.

Long Product Lifecycle: - Panel-mount industrial monitors are designed with a focus on longevity, providing a longer product lifecycle compared to consumer-grade monitors.

Cost Efficiency: - By eliminating the need for external enclosures, panel-mount monitors can contribute to cost savings in terms of materials and installation.

Versatile Connectivity: - Equipped with a range of connectivity options, including VGA, DVI, HDMI, USB, and serial ports, ensuring compatibility with a variety of industrial equipment and systems.

Reduced Maintenance Needs: - The rugged design and durability contribute to reduced maintenance requirements, lowering the overall cost of ownership.

Compact Design: - The compact form factor of panel-mount industrial monitors allows them to fit seamlessly into control panels, even in limited-space industrial environments.

These advantages collectively make panel-mount industrial monitors a practical and efficient solution for enhancing control and monitoring capabilities in industrial automation and control systems. |