Technology of panel mount touch screen monitorThe technology of a panel mount touch screen monitor involves the integration of various components and technologies to enable interactive and user-friendly functionality. Here are key aspects of the technology used in panel mount touch screen monitors: Touch Screen Technologies: - Resistive Touch Screen: Comprises multiple layers, and when pressure is applied, the layers make contact, determining the touch point.

- Capacitive Touch Screen: Relies on the electrical properties of the human body. When a conductive object (like a finger) touches the screen, it disrupts an electrical field, enabling touch detection.

- Infrared Touch Screen: Uses infrared sensors to detect touch points by recognizing interruptions in infrared beams across the screen's surface.

- Surface Acoustic Wave (SAW) Touch Screen: Relies on ultrasonic waves transmitted across the screen's surface. Touch disrupts the waves, and the touch point is detected.

- Projected Capacitive Touch Screen: Similar to capacitive touch screens but with a matrix of conductive material for more advanced touch and multitouch capabilities.

Panel Mount Design: - The monitor is designed with a form factor that allows secure and stable mounting directly onto panels, control panels, or other surfaces.

Display Technology: - Utilizes LCD (Liquid Crystal Display) or other display technologies to provide high-resolution and high-brightness visuals.

Enclosure and Housing: - The enclosure or housing is designed to be rugged and durable, often made from materials that can withstand environmental conditions and provide protection to internal components.

Controller Board: - Integrates a controller board that interprets touch inputs and communicates with the display, ensuring accurate and responsive touch functionality.

Connectivity Interfaces: - Includes various connectivity options such as USB, HDMI, VGA, and others, allowing seamless integration with control systems, computers, and other devices.

Processor and Electronics: - Houses a processor and electronic components that manage the overall functionality of the monitor, including touch processing, display rendering, and interface communication.

Environmental Protection: - May incorporate features for environmental protection, such as a sealed design to prevent dust and water ingress. The monitor may also be designed to operate in a wide range of temperatures.

Brightness and Clarity Enhancement: - Utilizes technologies to enhance brightness and clarity, including anti-glare coatings, high-brightness displays, and technologies to improve visibility in different lighting conditions.

Customization Options: - Some monitors offer customization options, allowing users to choose specific features such as touch screen technology, screen size, and additional functionalities based on their needs.

Multitouch Support: - Depending on the touch screen technology used, panel mount touch screen monitors may support multitouch functionality, allowing users to interact with the screen using multiple touch points.

User Interface Software: - Involves software components that manage the user interface, touch input processing, and any additional functionalities. This software is crucial for providing a seamless and user-friendly experience.

Calibration and Calibration Software: - Incorporates calibration features to ensure precise touch input accuracy. Calibration software allows users to align the touch screen with the display for optimal performance.

User Feedback Mechanisms: - May include haptic feedback or visual indicators to provide users with feedback when a touch input is registered.

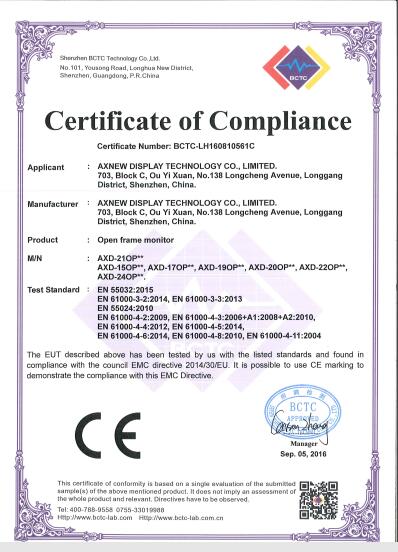

Compliance and Certification: - Ensures compliance with industry standards and certifications, especially in sectors with specific regulatory requirements.

The specific technology used can vary based on the manufacturer and model of the panel mount touch screen monitor. When selecting a panel mount touch screen monitor, it's essential to consider the specific requirements of the intended application and the environmental conditions it will be exposed to. | Applications of panle mount touch screen monitorPanel mount touch screen monitors find applications across various industries where interactive and user-friendly displays are essential. Here are some common applications: Industrial Automation and Control: - Used in control panels for industrial automation to monitor and control machinery, processes, and systems. The touch screen interface allows for intuitive control in manufacturing environments.

Human-Machine Interface (HMI) Systems: - Deployed as HMIs in industrial settings, enabling operators to interact with and monitor equipment, PLCs (Programmable Logic Controllers), and other control systems through a touch interface.

Information Kiosks: - Installed in public spaces, retail environments, and transportation hubs as information kiosks. Users can access information, maps, and services through the touch screen interface.

Medical Devices and Equipment: - Integrated into medical devices, diagnostic equipment, and healthcare systems to provide a user-friendly interface for medical professionals and patients.

Digital Signage and Advertising Displays: - Used in interactive digital signage and advertising displays for retail, hospitality, and public spaces. Users can engage with content and access additional information.

Gaming and Entertainment: - Integrated into gaming machines, arcade systems, and entertainment consoles to provide interactive gaming experiences with touch controls.

Retail Point of Sale (POS) Systems: - Utilized in retail environments as part of POS systems. Touch screen monitors allow for efficient and user-friendly transaction processing and inventory management.

Agricultural Machinery: - Integrated into agricultural machinery and equipment, such as tractors and harvesters, for monitoring and controlling various functions in the field.

Navigation Systems for Vehicles: - Installed in vehicles as part of navigation and entertainment systems, providing touch-based control for GPS, multimedia, and other features.

Air Traffic Control: - Used in air traffic control systems to monitor and manage air traffic. Touch screen interfaces facilitate efficient and quick decision-making.

Marine and Offshore Control Systems: - Integrated into marine and offshore control panels for navigation, monitoring, and control of ship systems.

Laboratory and Scientific Equipment: - Incorporated into laboratory equipment and scientific instruments for data visualization, control, and analysis.

Energy and Power Management: - Deployed in power plants and energy management systems for monitoring and controlling processes related to electricity generation and distribution.

Building Automation and Smart Homes: - Used in building automation systems and smart homes to control lighting, HVAC (Heating, Ventilation, and Air Conditioning), security, and other home automation features.

Training Simulators: - Integrated into training simulators for various industries, including aviation, military, and healthcare, providing realistic and interactive training environments.

Education and Interactive Whiteboards: - Applied in educational settings, especially for interactive whiteboards and displays, allowing teachers and students to interact with educational content.

Food and Beverage Ordering Systems: - Implemented in restaurants and food service establishments for self-service ordering and menu selection.

Security and Surveillance Systems: - Integrated into security and surveillance systems for monitoring and controlling cameras, alarms, and access control systems.

These applications showcase the versatility of panel mount touch screen monitors in enhancing human-machine interaction and improving efficiency across a wide range of industries. |