Detailed Product Description

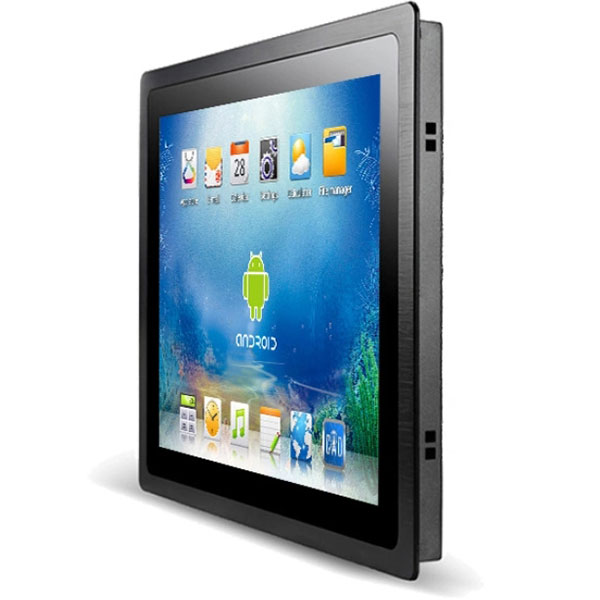

Industrial touch panel pc

An industrial touch panel PC is a specialized computing device designed for use in industrial environments. It integrates a touchscreen display with a ruggedized computer system, making it suitable for applications that require reliable and durable computing solutions in harsh or challenging conditions.

Key Components:Touch screen display+ruggedized computer system

Touch screen display"Touch screen display" refers to a display screen that is equipped with touch-sensitive technology, allowing users to interact with the display by directly touching it. These displays are commonly used in various electronic devices, including smartphones, tablets, computers, and industrial equipment. Touch screen displays enable users to navigate through applications, input data, and perform various tasks with the touch of a finger or a stylus.

ruggedized computer systemA "ruggedized computer system" refers to a computing device or system that is specifically designed and built to withstand harsh environmental conditions and physical stress. These systems are engineered to operate reliably in challenging settings where standard computers might fail. They are commonly used in industries such as military, aerospace, manufacturing, construction, and outdoor fieldwork. Ruggedized computer systems are typically built to resist factors like extreme temperatures, moisture, dust, vibrations, and shock, making them suitable for demanding applications in rugged environments.

|

|

|

|

15 inch industrial touch panel pc specifications

| Panel PC information |

|

| Model Number | AXD-15PPC-A5C |

| 15’’ Touch panel pc |

| Case/Bezel Color | Black |

| TFT Type | Industrial LCD with LED backlight |

| Aspect ratio | 4:3 |

| Touch Panel | Projected-capacitive Touch Flat Screen |

| Touch response time | 10ms (typical) |

| Optimal (native) Resolution | 1024×768 |

| LCD panel Pixel pitch | 0.264 x 0.264 mm |

| LCD panel Colors | 16.7 million |

| LCD panel Brightness | 350 cd/m2 |

| LCD panel Response Time | 8ms |

| Contrast Ratio | 800:1 |

| Viewing Angle ( Wide ) |

|

| Horizontal (left/right) | ±88° or 176° total |

| Vertical (up/down) | 88°(up), 88°(down) or 176° total |

| CPU | Soldered onboard Intel® I5 6200U 2.3GHz

Processor; DDR4 1600MHz SDRAM |

| storage | Brand new SATA SSD (128G/256G) |

| Serial Ports | 2 x COM ports (1x RS-232/422/485 by-pin connector) |

| USB Ports | 2 x USB external ports ; 6 six USB internal ports |

| LAN | 1 x LAN RJ-45 connector |

| Net | 1 x Realtek RTL8111C Gigabit Ethernet controller |

| DC Power In | 1 x 4-pin connector |

| Video Port | 1 x VGA/ 1x HDMI |

| Watch Dog Timer | 1~255 levels reset |

| Internal Sockets & Connectors | 1 x Compact Flash socket (reserved for OEM project) |

| Power Specification | DC 12V 5A |

| Working Environment |

| Temperature | Operating: -10°C to 70°C ;Storage -20°C to75°C |

| Operating Humidity | 5 ~ 90% RH @40°C (non-condensing |

| Vibration | 5 ~ 500Hz, 3Grms Random (with CF/SSD) |

| Shock | Operating 16G, 11ms & Non-operating 4G, 20ms (with |

| Dimensions |

| Mounting Type | Embedded Installation |

| Mechanical dimensions | 378x 297 x 68 mm |

| Weight (Net) | 6.0 kgs/ piece |

| Drawings | Please contact us for details |

Informations of 15 inch industrial touch panel pc

| Model: AXD-15PPC-A5C | Screen Size:15’’ |

| Screen format: 4:3 | Display Resolution(pixel):1024X768 |

| Contrast Ratio:800:1 | Brightness:350cd/m^2 |

| Operating temperature : -20℃~70℃ | Touch Type: Pro-CapacitiveTouch screen |

| Power Input: DC 12V | Product status: in production |

Detailed introduction to industrial touch panel pc

Specifications of industrial touch panel pc | Features of industrial touch panel pc

| Classification of industrial touch panel pc |

Applications of industrial touch panel pc

| Technology of industrial touch panel pc

| Process of industrial touch panel pc

|

Industrial touch panel pc customization | Advantages of industrial touch panel pc | Rugged Design for industrial touch panel pc |

High-Performance Computing of industrial touch panel pc | Interactive Touchscreen Interface for industrial touch panel pc | Customization Options of industrial touch panel pc |

Wide Operating Temperature Range for industrial touch panel pc | Versatile Mounting Solutions of industrial touch panel pc | Extensive I/O Ports and Expansion Slots of industrial touch panel pc |

Dust and Water Resistance (IP Rating) of touch panel pc | Long-Term Reliability of industrial touch panel pc | Enhanced Productivity and Efficiency of industrial touch panel pc |

Critical Role in Industry 4.0 and IoT of industrial touch panel pc | Integration with SCADA Systems of industrial touch panel pc | Industry-Specific Applications of industrial touch panel pc |

Specifications of industrial touch panel pc

The specifications of an industrial touch panel PC can vary based on the specific model and manufacturer. However, here are some common specifications to consider:

Processor:

- Type (e.g., Intel Core i5, i7)

- Clock Speed (GHz)

- Number of Cores

Memory (RAM):

- Capacity (e.g., 4GB, 8GB, 16GB)

- Type (e.g., DDR4)

Storage:

- Type (e.g., SSD, HDD)

- Capacity (e.g., 128GB, 256GB, 1TB)

- Additional Storage Options (e.g., mSATA, M.2 slots)

Display:

- Screen Size (inches)

- Resolution (e.g., Full HD, 4K)

- Touch Technology (e.g., Capacitive, Resistive)

- Brightness (nits)

- Viewing Angle

Graphics:

- Integrated GPU or Dedicated Graphics Card (if applicable)

Operating System Compatibility:

Input/Output Ports:

- USB Ports (Type-A, Type-C)

- Ethernet Ports

- Serial Ports (RS-232/RS-485)

- HDMI/DVI/VGA Ports

- Audio Ports

Wireless Connectivity:

Power Supply:

- Input Voltage (e.g., 100-240V AC)

- Power Consumption (Watts)

Mounting Options:

- Panel Mount, VESA Mount, Rack Mount, Standalone

Environmental Ratings:

- Operating Temperature Range (°C)

- IP Rating (Dust and Water Resistance)

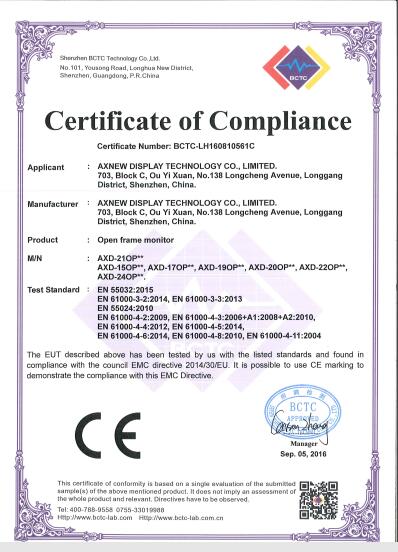

Certifications:

- Industry-specific Certifications (e.g., CE, FCC)

Ruggedization Features:

- Shock and Vibration Resistance

- Fanless Design

- Protective Enclosure Material

Expansion Slots:

- PCIe, Mini PCIe, M.2 slots, etc.

Dimensions and Weight:

- Width x Height x Depth (mm or inches)

- Weight (kg or lbs)

Additional Features:

- Fanless Cooling System

- TPM (Trusted Platform Module) for Security

- Watchdog Timer

- Backup Battery (for power loss protection)

It's important to note that these specifications are indicative, and actual specifications may vary based on the specific model and manufacturer of the industrial touch panel PC. When considering a specific model, it's recommended to refer to the manufacturer's datasheet or product documentation for precise and up-to-date information.

Features of industrial touch panel pc

| Industrial touch panel PCs are specialized computing devices designed to operate in demanding industrial environments. They offer a range of features tailored to meet the unique requirements of industrial applications. Here are some key features of industrial touch panel PCs:

Rugged Construction: - Built to withstand harsh environmental conditions including dust, moisture, vibrations, and temperature extremes.

Touchscreen Interface: - Equipped with a responsive touchscreen display, allowing for intuitive and direct interaction with the system.

High-Performance Computing: - Powerful processors and ample memory to handle complex industrial applications and multitasking.

Customization Options: - Flexible configurations to accommodate specific industrial requirements, including I/O ports, expansion slots, and peripherals.

Wide Operating Temperature Range: - Capable of functioning reliably in environments with extreme temperature variations.

Dust and Water Resistance (IP Rating): - Provides a level of protection against dust and water ingress, ensuring durability in challenging conditions.

Vibration and Shock Resistance: - Engineered to withstand mechanical stress and vibrations often present in industrial settings.

Fanless Design: - Eliminates the need for cooling fans, reducing the risk of dust and debris accumulation and increasing system reliability.

Multiple Mounting Options: - Can be panel-mounted, VESA-mounted, rack-mounted, or used as standalone units, providing versatility in installation.

Wide Range of I/O Ports: - Multiple input/output ports for connecting to external devices, sensors, and industrial equipment.

Long-Term Reliability: - Utilizes high-quality components and materials to ensure extended service life and minimize downtime.

Enhanced Security Features: - Supports security measures like TPM (Trusted Platform Module) for data protection and secure boot.

Power Loss Protection: - Backup battery or capacitors to ensure data integrity and system stability in case of sudden power outages.

Compatibility with Industry Standards: - Designed to meet specific industry standards and certifications for reliable operation in industrial environments.

Integration with SCADA Systems: - Compatibility with Supervisory Control and Data Acquisition (SCADA) systems for real-time monitoring and control.

IoT Connectivity: - Ability to connect to IoT networks and platforms for data collection, analysis, and integration with broader industrial systems.

Flexible Expansion Options: - Additional slots for expansion cards, allowing for integration of specialized hardware or additional functionalities.

These features collectively make industrial touch panel PCs an essential component in a wide range of industrial applications, contributing to improved efficiency, productivity, and reliability in demanding environments.

|

Classification of industrial touch panel pc

Industrial touch panel PCs can be classified based on various factors. Here are some common classification categories: Based on Form Factor: - Panel Mount PCs: Designed to be embedded directly into a control panel or enclosure.

- Rack Mount PCs: Installed in standard rack units, commonly used in server rooms or industrial cabinets.

- Open Frame PCs: Designed without an enclosure, allowing for integration into custom-built systems.

Based on Screen Size: - Small Form Factor (e.g., 7 inches to 15 inches)

- Medium Form Factor (e.g., 15 inches to 24 inches)

- Large Form Factor (e.g., 24 inches and above)

Based on Touch Technology: - Resistive Touch Panel PCs: Utilize pressure-sensitive touchscreens, cost-effective and durable.

- Capacitive Touch Panel PCs: Detect touch through electrical properties of the human body, provide high responsiveness.

- Infrared Touch Panel PCs: Use infrared sensors to detect touch, suitable for harsh environments.

Based on Processing Power: - Entry-Level Industrial Touch Panel PCs: Basic computing power for simple applications.

- Mid-Range Industrial Touch Panel PCs: Offers moderate processing capabilities for more complex tasks.

- High-Performance Industrial Touch Panel PCs: Equipped with powerful processors for demanding applications.

Based on Environmental Ratings: - IP65/IP66/IP67 Rated PCs: Provide varying levels of protection against dust and water.

- NEMA Rated PCs: Designed to meet specific standards set by the National Electrical Manufacturers Association.

Based on Industry/Application: - Factory Automation: Designed for use in manufacturing and automation processes.

- HMI (Human Machine Interface): Customized for interaction between operators and industrial machines.

- Control Systems: Tailored for monitoring and controlling industrial processes.

- Marine and Offshore: Built to withstand maritime environments.

- Medical and Healthcare: Compliant with healthcare standards for medical equipment control.

- Transportation: Designed for use in vehicles or transportation systems.

Based on Connectivity: - Wired Industrial Touch Panel PCs: Emphasis on wired connectivity options like Ethernet, USB, serial ports, etc.

- Wireless Industrial Touch Panel PCs: Equipped with wireless communication capabilities (Wi-Fi, Bluetooth, etc.).

Based on Specialized Features: - ATEX Certified PCs: Designed for use in potentially explosive atmospheres.

- Sunlight Readable PCs: Equipped with high-brightness displays for outdoor or high-ambient light environments.

- Fanless Industrial Touch Panel PCs: Designed without fans for enhanced reliability and reduced maintenance.

These classifications help users and industry professionals in selecting the most suitable industrial touch panel PC for their specific application and environmental conditions. |

|

Applications of industrial touch panel pc

Industrial touch panel PCs find applications in a wide range of industries and environments where robust, reliable, and interactive computing solutions are needed. Here are some common applications:

Factory Automation:

- Used to control and monitor automated manufacturing processes, ensuring efficient production.

HMI (Human Machine Interface):

- Serve as the interface between operators and machinery in industrial settings, enabling control and data visualization.

Control Systems:

- Implemented in critical infrastructure sectors like energy, water, and transportation for monitoring and controlling processes.

Marine and Offshore:

- Utilized in maritime environments for navigation, communication, and control systems on ships and offshore platforms.

Medical and Healthcare:

- Integrated into medical equipment for patient monitoring, diagnostic imaging, and data recording.

Transportation and Logistics:

- Installed in vehicles for fleet management, route planning, navigation, and real-time tracking.

Oil and Gas Industry:

- Employed in drilling operations, pipeline monitoring, and control systems for oil and gas facilities.

Agriculture and Farming:

- Used in precision agriculture applications for monitoring and controlling agricultural machinery and systems.

Food and Beverage Industry:

- Integrated into food processing and packaging equipment for process control and monitoring.

Utilities and Energy Management:

- Used in power generation and distribution facilities for monitoring and controlling energy production and consumption.

Environmental Monitoring:

- Deployed in environmental monitoring systems to collect and analyze data related to air quality, water quality, etc.

Pharmaceutical Industry:

- Integrated into equipment for pharmaceutical production and research, ensuring precision and compliance.

Building Automation:

- Used in smart building systems for HVAC control, lighting control, access control, and energy management.

Mining and Construction:

- Deployed in rugged environments for equipment control, data collection, and safety monitoring.

Retail and Point of Sale (POS):

- Integrated into self-service kiosks, POS systems, and interactive displays for retail applications.

Security and Surveillance:

- Utilized in video surveillance systems for real-time monitoring and control.

Water Treatment and Wastewater Management:

- Employed for monitoring and controlling processes in water treatment plants and wastewater facilities.

Educational and Training Simulators:

- Used in simulations and training systems for educational purposes in various industries.

Gaming and Entertainment:

- Integrated into interactive kiosks, gaming machines, and entertainment systems.

These applications showcase the versatility and importance of industrial touch panel PCs in optimizing processes, enhancing control, and improving efficiency across a wide range of industries and sectors.

|

|

Technology of industrial touch panel pcThe technology behind industrial touch panel PCs encompasses various components and innovations that enable their functionality and suitability for demanding industrial environments. Here are key aspects of the technology involved: Ruggedized Design: - Industrial touch panel PCs are engineered with ruggedized components and enclosures to withstand harsh environmental conditions, including dust, moisture, vibrations, and temperature extremes.

Touchscreen Technology: - Capacitive, resistive, or infrared touchscreens are commonly used in industrial touch panel PCs. Each technology has its own method of detecting and responding to touch gestures.

Processing Power: - These PCs are equipped with processors capable of handling the computational demands of industrial applications. This includes both standard processors (e.g., Intel, AMD) and specialized processors for industrial computing.

Memory and Storage: - Industrial touch panel PCs have sufficient RAM and storage to run industrial applications efficiently. Solid-state drives (SSDs) are often used for fast and reliable storage.

Connectivity: - They are equipped with a range of input/output ports, including USB, Ethernet, serial, and others, to connect to various industrial equipment and peripherals.

Fanless Cooling System: - Many industrial touch panel PCs incorporate fanless cooling designs, which use passive cooling methods to dissipate heat. This reduces the risk of dust and debris accumulation and increases system reliability.

Embedded Operating Systems: - Industrial touch panel PCs often run on specialized embedded operating systems optimized for industrial applications. These may include Windows Embedded, Linux-based OS, or other industry-specific platforms.

Display Technology: - Industrial touch panel PCs may utilize advanced display technologies such as LED-backlit LCDs with high brightness levels and wide viewing angles. Some may also incorporate features like anti-glare or anti-reflective coatings.

Environmental Protection: - These PCs are designed to meet specific environmental ratings, such as IP (Ingress Protection) ratings, indicating their level of protection against dust and water.

Power Management: - Industrial touch panel PCs may include power management features, such as low-power modes or the ability to operate on a wide range of input voltages.

Security Features: - Security measures like Trusted Platform Module (TPM) may be integrated to enhance data security and system integrity.

Customization Options: - Manufacturers may offer customization options for specific I/O ports, expansion slots, and other features to meet the unique requirements of industrial applications.

Certifications and Compliance: - Industrial touch panel PCs may undergo certification processes to meet industry-specific standards and regulations, ensuring their suitability for various industrial sectors.

IoT and Connectivity: - Some industrial touch panel PCs are equipped with connectivity features to integrate with IoT networks and platforms for data collection, analysis, and integration with broader industrial systems.

These technological components work together to create a reliable and efficient computing solution tailored for use in industrial environments. They provide the necessary functionality and durability to meet the demanding requirements of industrial applications. | Process of industrial touch panel pcThe process of manufacturing an industrial touch panel PC involves several stages, from design and component selection to assembly and testing. Here is a simplified overview of the typical process: Design and Specification: - The process begins with the design phase, where engineers create the blueprint for the industrial touch panel PC. This includes selecting the form factor, choosing the appropriate components, and defining the layout of the touchscreen interface.

Component Procurement: - Once the design is finalized, the necessary components are sourced. This includes the processor, memory, storage, touchscreen display, I/O ports, and other specialized components required for industrial-grade performance.

PCB Design and Manufacturing: - Printed Circuit Boards (PCBs) are designed to connect and integrate all the components. The PCB layout is crucial for ensuring proper functionality and reliability. Once designed, the PCBs are manufactured.

Assembly: - The assembly process involves placing and soldering components onto the PCB. This includes the processor, memory modules, storage devices, connectors, and other electronic components.

Touchscreen Integration: - The touchscreen panel is integrated into the display assembly. This involves carefully aligning and securing the touchscreen to ensure accurate touch response.

Enclosure Manufacturing: - The enclosure or chassis of the touch panel PC is fabricated. The enclosure is designed to be rugged and protective, capable of withstanding harsh industrial environments. It is often made from durable materials like metal or specialized plastics.

Final Assembly: - The PCB, display assembly, and enclosure are brought together in the final assembly stage. The components are securely mounted within the enclosure, and all necessary connections are made.

Software Installation: - The necessary software, including the operating system and any specialized industrial applications, is installed onto the touch panel PC.

Quality Control and Testing: - The assembled unit undergoes rigorous testing to ensure functionality, reliability, and compliance with specifications. This includes testing the touchscreen interface, verifying I/O ports, checking for any hardware or software issues, and conducting environmental testing if required.

Burn-In Testing: - Some manufacturers perform burn-in testing, which involves running the touch panel PC under stress conditions for an extended period to identify any potential reliability issues.

Final Inspection: - The touch panel PC undergoes a final inspection to verify that it meets all quality standards and specifications. Any necessary adjustments or corrections are made.

Packaging and Shipping: - Once the touch panel PC passes all tests and inspections, it is carefully packaged to ensure it arrives at its destination in optimal condition.

Throughout each stage of the process, strict quality control measures are implemented to ensure that the industrial touch panel PC meets the high standards required for reliable operation in industrial environments. |

Industrial touch panel pc customization

Industrial touch panel PCs can often be customized to meet specific requirements and preferences. Here are some aspects that can be customized:

Form Factor and Size:

- Custom dimensions and form factors can be designed to fit specific enclosures or spaces.

Touchscreen Technology:

- Depending on the application, different touchscreen technologies (capacitive, resistive, infrared) can be chosen for optimal performance.

Processor and Performance:

- The processor can be selected based on the computing power required for the specific industrial application.

Memory and Storage:

- The amount of RAM and storage capacity can be customized to meet specific performance and storage needs.

I/O Ports:

- The types and number of I/O ports (USB, Ethernet, serial, etc.) can be adjusted to match the connectivity requirements of the application.

Operating System and Software:

- Customized operating systems or specialized software can be pre-installed to streamline operations.

Enclosure Material and Ruggedization:

- The material of the enclosure can be customized based on the environmental conditions. Ruggedization features can also be added for increased durability.

Environmental Protection (IP Rating):

- The degree of protection against dust and water ingress can be specified to suit the application's environment.

Mounting Options:

- Customized mounting options (panel mount, VESA mount, rack mount, etc.) can be provided for specific installation requirements.

Additional Features:

- Specific features like fanless cooling, sunlight readability, ATEX/IECEx certification for hazardous areas, or backup power options can be added.

Brand and Labeling:

- Custom branding, logos, and labels can be applied to the touch panel PC to reflect the company's identity.

Certifications and Compliance:

- The touch panel PC can be designed to meet specific industry standards and regulatory requirements.

Long-Term Support and Service:

- Customized service and support plans can be tailored to meet the specific needs of the customer.

Specialized Software Integration:

- Custom software solutions or applications can be integrated to meet unique operational requirements.

Testing and Validation:

- Customized testing procedures can be established to ensure that the touch panel PC meets all specified requirements.

Documentation and Manuals:

- Customized user manuals, documentation, and training materials can be provided.

It's important to work closely with the manufacturer or supplier during the customization process to ensure that all specifications are accurately communicated and implemented. This collaborative approach helps to create a tailored solution that precisely meets the needs of the industrial application.

Advantages of industrial touch panel pc

| Industrial touch panel PCs offer several advantages that make them well-suited for a wide range of industrial applications. Here are some key advantages: Rugged and Durable: - Designed to withstand harsh environmental conditions, including exposure to dust, moisture, vibrations, and extreme temperatures. This ensures long-term reliability in demanding industrial settings.

Intuitive Interface: - The touchscreen interface provides an intuitive and user-friendly interaction method, eliminating the need for external peripherals like keyboards and mice.

Space-Saving Design: - Industrial touch panel PCs are often compact and can be mounted directly into control panels or enclosures, saving valuable space in industrial environments.

Reduced Maintenance: - Fanless designs reduce the risk of dust and debris accumulation, minimizing maintenance requirements and increasing system reliability.

Increased Productivity: - The touchscreen interface allows for quick and direct access to controls and information, improving operational efficiency and reducing response times.

Customizable Configurations: - Industrial touch panel PCs can be customized to meet specific application requirements, including variations in size, processing power, I/O ports, and touchscreen technology.

Versatility in Mounting Options: - They can be panel-mounted, VESA-mounted, rack-mounted, or used as standalone units, providing flexibility in installation.

Compatibility with Industrial Software: - Designed to run specialized industrial software and applications, making them ideal for tasks like process monitoring, control, and data analysis.

Reliable in Extreme Environments: - Engineered to operate in environments with wide temperature ranges, making them suitable for applications in industries like manufacturing, oil and gas, and transportation.

Enhanced Security Features: - Some models offer advanced security features like TPM (Trusted Platform Module) for data protection, ensuring the integrity and confidentiality of sensitive information.

Long-Term Availability and Support: - Industrial touch panel PCs are typically designed for long-term use, with extended product life cycles and availability of spare parts.

Integration with Industrial Equipment: - Equipped with a wide range of I/O ports, they can seamlessly connect to various industrial equipment, sensors, and peripherals.

Real-Time Monitoring and Control: - Used as HMIs (Human Machine Interfaces) in control systems, allowing operators to monitor and control processes in real-time.

Compliance with Industry Standards: - Designed to meet specific industry standards and certifications, ensuring compliance with regulatory requirements.

Support for Industry 4.0 and IoT: - They play a crucial role in the implementation of Industry 4.0 initiatives by providing a central interface for data collection, analysis, and integration with IoT networks.

These advantages collectively make industrial touch panel PCs an indispensable tool in various industries, contributing to improved efficiency, productivity, and reliability in challenging industrial environments. |

Future of industrial touch panel pc

The future of industrial touch panel PCs is likely to be shaped by several technological trends and industry-specific demands. Here are some potential developments we can anticipate:

Integration with Industry 4.0 and IoT:

- Industrial touch panel PCs will play a central role in the implementation of Industry 4.0 initiatives, facilitating seamless connectivity and communication between machines, systems, and IoT devices.

AI and Machine Learning Integration:

- Touch panel PCs may incorporate AI capabilities for real-time data analysis, predictive maintenance, and intelligent decision-making in industrial processes.

Enhanced Touchscreen Technology:

- Advancements in touchscreen technology, such as more precise capacitive touchscreens and haptic feedback, will provide more intuitive and responsive user interfaces.

Edge Computing Capabilities:

- Industrial touch panel PCs may have enhanced processing power and storage capacity to support edge computing, allowing for faster data processing and reduced reliance on cloud resources.

Advanced Ruggedization and Durability:

- Future touch panel PCs may be designed to withstand even more extreme environmental conditions, ensuring continued operation in the harshest industrial settings.

Augmented Reality (AR) and Virtual Reality (VR):

- Integration of AR and VR technologies into industrial touch panel PCs could revolutionize training, maintenance, and troubleshooting processes in industrial environments.

Gesture and Voice Control:

- Touch panel PCs may incorporate gesture and voice recognition technologies to provide alternative means of interaction, particularly in situations where hands-free operation is crucial.

Energy Efficiency and Power Management:

- Future touch panel PCs may incorporate more efficient components and power management features to reduce energy consumption and support sustainable operations.

Cybersecurity Enhancements:

- With the increasing connectivity of industrial systems, touch panel PCs will likely include advanced cybersecurity features to protect against cyber threats and ensure data integrity.

Multi-Modal Interfaces:

- Touch panel PCs may support a combination of touch, gesture, voice, and even biometric inputs to provide users with a diverse set of interaction options.

AI-Driven Predictive Maintenance:

- Touch panel PCs may utilize AI algorithms to predict and schedule maintenance tasks based on real-time data, minimizing downtime and optimizing equipment performance.

Customization and Flexibility:

- Future touch panel PCs will continue to offer a high degree of customization to meet specific industry and application requirements.

Continued Miniaturization and Integration:

- Ongoing advancements in technology may lead to smaller, more compact touch panel PCs with integrated components, providing even greater versatility in mounting and installation.

The future of industrial touch panel PCs will likely be marked by a convergence of technologies aimed at enhancing performance, connectivity, and user interaction, ultimately contributing to more efficient and productive industrial operations.

Rugged Design for industrial touch panel pc

A rugged design for industrial touch panel PCs is crucial to ensure reliable performance in harsh and demanding environments. Here are key elements of a rugged design:

Robust Enclosure:

- Constructed from durable materials like metal or specialized industrial-grade plastics to provide protection against physical impacts, vibration, and environmental elements.

Sealed and Gasketed Construction:

- Designed with sealed and gasketed edges to prevent the ingress of dust, dirt, water, and other contaminants. This helps maintain the integrity of internal components.

IP Rating:

- Certified with a specific Ingress Protection (IP) rating indicating the degree of protection against dust and water. Higher IP ratings indicate greater resistance to environmental factors.

Shock and Vibration Resistance:

- Engineered to withstand shocks and vibrations commonly encountered in industrial settings, ensuring stable operation even in rugged conditions.

Wide Temperature Range:

- Capable of operating within a wide temperature range, from extreme cold to high heat, to accommodate various industrial environments.

Fanless Cooling System:

- Utilizes passive cooling methods, such as heat sinks or thermal management techniques, to eliminate the need for cooling fans that could be susceptible to dust and debris buildup.

Chemical and Corrosion Resistance:

- Treated with specialized coatings or materials to resist damage from exposure to chemicals, oils, solvents, and corrosive substances often found in industrial environments.

EMI/RFI Shielding:

- Equipped with shielding measures to protect against electromagnetic interference (EMI) and radio frequency interference (RFI) that can affect electronic components.

Sunlight Readability:

- Enhanced display technology with high brightness levels and anti-glare or anti-reflective coatings to ensure visibility in bright outdoor or high-ambient light conditions.

Mounting Options:

- Designed with a variety of mounting options, including panel mount, VESA mount, rack mount, and others, to accommodate different installation requirements.

Sealed Connectors:

- Utilizes sealed and secure connectors to prevent water and dust ingress through I/O ports.

Vibration-Dampening Components:

- Incorporates shock-absorbing materials or mechanisms to reduce the impact of vibrations on internal components.

Tamper-Resistant Design:

- Designed to deter unauthorized access and tampering, with features like locking mechanisms and sealed access points.

High Reliability Components:

- Uses industrial-grade components known for their durability and longevity, ensuring continued operation in challenging environments.

Compliance with Industry Standards:

- Designed and tested to meet industry-specific standards and certifications for ruggedness and reliability.

A rugged design for industrial touch panel PCs is essential for ensuring consistent and reliable performance in the demanding conditions of industrial environments. It helps minimize downtime, reduce maintenance costs, and extend the operational life of the equipment.

High-Performance Computing of industrial touch panel pcHigh-performance computing in industrial touch panel PCs involves the integration of powerful hardware components and optimized software to handle complex tasks and processes efficiently. Here are key aspects of high-performance computing in these systems: Powerful Processors: - Incorporation of high-performance processors, such as Intel Core i7 or Xeon processors, with multiple cores and high clock speeds for rapid data processing.

Advanced Graphics Processing Units (GPUs): - Inclusion of dedicated GPUs with high processing power for applications that require intensive graphics processing, like visualizations and simulations.

Ample RAM: - Provision of substantial RAM capacity (16GB or more) to support multitasking and the handling of large datasets or complex calculations.

SSD Storage: - Utilization of Solid-State Drives (SSDs) for fast and reliable storage, allowing for quick data access and reduced boot times.

Parallel Processing Capabilities: - Support for parallel processing techniques and multi-threaded applications to accelerate computations and data analysis.

Optimized Operating Systems: - Use of specialized or optimized operating systems (such as Windows Embedded or Linux-based platforms) that are streamlined for industrial applications.

GPU Accelerated Computing: - Integration of GPU acceleration technologies (e.g., CUDA or OpenCL) to offload parallelizable tasks to the GPU for faster processing.

Hardware Accelerators: - Inclusion of specialized hardware accelerators or co-processors for specific tasks like encryption, decryption, or AI/ML processing.

Data Bus Speeds: - Employment of high-speed data buses and interfaces (e.g., PCIe, USB 3.0/3.1) to facilitate rapid data transfer between components and peripherals.

Low Latency Networking: - Integration of Gigabit or higher-speed Ethernet ports for low-latency communication between the touch panel PC and networked devices.

Customizable Expansion Slots: - Provision of PCIe slots for adding additional specialized cards or modules, such as fieldbus communication cards or AI accelerators.

Real-Time Processing Capabilities: - Support for real-time processing requirements, ensuring that critical tasks are executed within specified time constraints.

Software Optimization: - Optimization of software applications to leverage the full capabilities of the hardware, including utilizing parallel processing and GPU acceleration where applicable.

Thermal Management: - Implementation of effective thermal solutions to dissipate heat generated by high-performance components, ensuring stable and reliable operation.

Certifications for Industrial Use: - Compliance with industrial standards and certifications to guarantee that the touch panel PC can meet the demands of industrial applications.

By integrating these high-performance computing features, industrial touch panel PCs can handle complex tasks, process large volumes of data, and execute demanding applications with speed and efficiency, making them suitable for a wide range of industrial applications. | Interactive Touchscreen Interface for industrial touch panel pcAn interactive touchscreen interface for an industrial touch panel PC is a critical component that allows users to interact with and control industrial processes and applications. Here are key considerations for designing an effective interactive touchscreen interface: Intuitive Navigation: - Design a user-friendly interface with intuitive navigation menus and clear pathways to access different functions and information.

Clear and Concise Labels: - Use easily understandable labels and icons to indicate the purpose and function of each button or control element.

Responsive Touchscreen: - Ensure the touchscreen is highly responsive to touch gestures, providing immediate feedback to user inputs.

Consistent Layout and Design: - Maintain a consistent layout and design throughout the interface to provide a cohesive and familiar user experience.

Optimized for Gloved Hands: - If users will be wearing gloves, consider using larger buttons and controls to accommodate for the reduced precision of touch input.

Multi-Touch Support: - If applicable, ensure the touchscreen supports multi-touch gestures for tasks like zooming, pinching, and rotating.

Visual Feedback for Touch Inputs: - Provide visual feedback (e.g., button press animation) to confirm that a touch input has been registered.

Customizable Interface Elements: - Allow users to customize certain aspects of the interface, such as arranging shortcuts or selecting preferred display options.

Error Prevention and Handling: - Implement safeguards to prevent accidental inputs, and provide clear error messages or prompts for incorrect actions.

Accessibility Considerations: - Design the interface with accessibility features in mind, such as providing alternative text for visual elements and ensuring compatibility with screen readers.

Real-Time Data Display: - Display critical real-time data prominently on the interface, ensuring operators have immediate access to important information.

Toggleable Views or Modes: - Allow users to switch between different views or modes to access specific sets of controls or information relevant to different tasks.

Status Indicators: - Include visual indicators to display the status of equipment, processes, or alarms, providing immediate feedback on system conditions.

HMI Software Customization: - Utilize specialized Human Machine Interface (HMI) software that allows for the creation of custom interfaces tailored to specific industrial applications.

Testing and User Feedback: - Conduct usability testing with actual users to gather feedback and make refinements to the interface design for optimal user satisfaction and efficiency.

Regular Updates and Maintenance: - Continuously evaluate and update the interface based on user feedback, evolving requirements, and emerging technologies.

An effective interactive touchscreen interface is crucial for enabling operators and users to efficiently control and monitor industrial processes. It should be designed with user needs, task efficiency, and usability in mind to enhance overall productivity and operational effectiveness. |

Customization Options of industrial touch panel pc

Customization options for industrial touch panel PCs can be tailored to meet specific industry and application requirements. Here are some common customization options available:

Form Factor and Size:

- Customize the dimensions and form factor to fit specific enclosures, cabinets, or mounting locations within an industrial setting.

Processor Selection:

- Choose from a range of processors with varying levels of computing power to match the performance requirements of the application.

RAM and Storage Capacity:

- Select the amount of RAM and storage capacity needed to handle the computational demands and storage requirements of the application.

Touchscreen Technology:

- Opt for specific touchscreen technologies (resistive, capacitive, infrared, etc.) based on the application's environmental conditions and user preferences.

Operating System:

- Install a customized or specialized operating system tailored to the specific requirements of the industrial application.

I/O Ports and Expansion Slots:

- Customize the types and number of I/O ports (USB, Ethernet, serial, GPIO, etc.) and expansion slots (PCIe, Mini-PCIe) to accommodate the required connectivity.

Specialized Hardware Integration:

- Integrate specialized hardware components, such as fieldbus communication cards, AI accelerators, or additional serial ports, to meet unique application needs.

Graphics and Display Options:

- Customize display specifications, including resolution, brightness levels, and additional features like sunlight readability or anti-glare coatings.

Ruggedization and Environmental Protection:

- Specify the level of ruggedization (IP rating) and environmental protection features needed to ensure reliable operation in harsh industrial environments.

Certifications and Compliance:

- Customize the touch panel PC to meet specific industry standards or regulatory certifications required for the target application or market.

Custom Bezels and Front Panels:

- Design custom bezels and front panels to incorporate branding, logos, labels, or additional controls specific to the application.

Power Supply Options:

- Customize the power input options (AC, DC, PoE) to align with the available power sources in the industrial environment.

Mounting Solutions:

- Provide various mounting options (panel mount, VESA mount, rack mount, etc.) to accommodate specific installation requirements.

HMI Software Development:

- Develop or customize Human Machine Interface (HMI) software to create a user interface tailored to the specific needs of the application.

Long-Term Support and Service:

- Establish customized service and support plans to address specific maintenance, warranty, and technical support needs.

Custom Labeling and Branding:

- Apply custom labeling, branding, or silkscreen printing to the enclosure to reflect the company's identity.

Working closely with a manufacturer or supplier with expertise in industrial touch panel PCs is crucial to ensure that all customization options are accurately communicated and implemented to meet the unique requirements of the application.

Wide Operating Temperature Range for industrial touch panel pc

A wide operating temperature range is a critical feature for industrial touch panel PCs, as they are often deployed in environments with extreme temperature variations. Here are key considerations related to wide operating temperature ranges:

Definition of Operating Temperature Range:

- Specify the minimum and maximum temperatures at which the touch panel PC can reliably operate. This range is typically defined in degrees Celsius (°C).

Extreme Cold Tolerance:

- Ensure the touch panel PC can operate reliably in extremely cold environments, such as those found in refrigeration units, cold storage facilities, or outdoor installations in winter.

High Temperature Resistance:

- Verify that the touch panel PC can withstand high temperatures commonly found in industrial settings, especially in environments with heat-generating machinery or processes.

Thermal Management Solutions:

- Implement advanced thermal management techniques, such as heat sinks, fans, or heat pipes, to regulate internal temperatures and prevent overheating.

Component Selection:

- Choose industrial-grade components that are specifically designed to operate within a wide temperature range, ensuring reliability and longevity.

Sealed Enclosures:

- Utilize sealed and gasketed enclosures to prevent the ingress of dust, dirt, and moisture, which can impact the internal components and performance.

Thermal Insulation:

- Incorporate insulation materials to help maintain stable internal temperatures, especially in environments with significant temperature fluctuations.

Low-Temperature Startup:

- Ensure that the touch panel PC can reliably start up and operate even at the lower end of the specified temperature range, without the need for external heating or pre-warming.

Temperature Monitoring and Alerts:

- Implement temperature monitoring systems with alerts or warnings to notify operators if the touch panel PC approaches or exceeds its specified operating limits.

Testing and Certification:

- Conduct rigorous testing under extreme temperature conditions to validate the touch panel PC's performance and compliance with specified temperature ranges.

Design for Ventilation:

- Incorporate ventilation systems or slots to facilitate airflow and heat dissipation, especially in environments prone to temperature buildup.

Conformal Coating:

- Apply a conformal coating to circuit boards and components to provide an additional layer of protection against environmental factors, including temperature extremes.

Compatibility with Extended Temperature Components:

- Ensure that all internal components, including processors, memory modules, and storage devices, are rated for extended temperature operation.

Compliance with Industry Standards:

- Ensure that the touch panel PC complies with relevant industry standards for temperature resistance and environmental durability.

By addressing these considerations, an industrial touch panel PC with a wide operating temperature range can reliably function in challenging environments, providing continuous operation and minimizing downtime due to temperature-related issues.

| Versatile Mounting Solutions of industrial touch panel pcVersatile mounting solutions for industrial touch panel PCs are crucial to ensure they can be securely installed in a wide range of industrial environments. Here are some common mounting options: Panel Mounting: - Designed to be directly integrated into an equipment panel or enclosure, providing a flush and secure fit. This is ideal for applications where space is limited.

VESA Mounting: - Utilizes the VESA (Video Electronics Standards Association) standard for mounting displays on brackets or arms. This allows for easy adjustment of viewing angles.

Rack Mounting: - Designed to be installed in standard server racks or enclosures, making it suitable for applications in control rooms or data centers.

Open Frame Mounting: - Provides a bare-bones frame that can be customized for specific mounting requirements, making it versatile for various industrial setups.

Flush Mounting: - Ensures the touch panel PC sits flush with a surface, which is important for applications where a seamless and aesthetic appearance is desired.

Standalone/Desktop Mounting: - Allows the touch panel PC to be placed on a flat surface or desk, providing flexibility in positioning and accessibility.

Swivel Arm Mounting: - Uses an adjustable arm that allows the touch panel PC to be swiveled or tilted for optimal viewing angles. This is useful for applications where operators need to interact with the display from various positions.

Ceiling Mounting: - Enables the touch panel PC to be suspended from the ceiling, providing an overhead viewing angle. This is suitable for applications like industrial automation or surveillance systems.

Pole Mounting: - Involves attaching the touch panel PC to a vertical pole or post, which is commonly used in outdoor or field applications.

Articulating Arm Mounting: - Employs a multi-jointed arm that allows for a wide range of motion and positioning options, providing maximum flexibility in adjusting the viewing angle.

Wall Mounting: - Fixes the touch panel PC securely to a wall, making it suitable for applications where space is limited or where a fixed viewing angle is preferred.

Hazardous Area Mounting: - Specifically designed for installations in hazardous environments, ensuring compliance with safety regulations and providing protection against potential risks.

Mobile Cart Mounting: - Incorporates the touch panel PC into a mobile cart or stand, allowing for easy transport and maneuverability within a facility.

Vehicle Mounting: - Customized mounting solutions designed for installation in vehicles, such as trucks, forklifts, or industrial vehicles, enabling real-time monitoring and control during operation.

Adjustable Stand Mounting: - Offers a stable stand with adjustable height, tilt, and swivel options for ergonomic positioning and user comfort.

Choosing the appropriate mounting solution for an industrial touch panel PC depends on factors such as the application environment, available space, viewing angles, and ergonomic considerations. It's important to work with a manufacturer or supplier with expertise in industrial installations to ensure the chosen mounting solution meets the specific needs of the application. |

Extensive I/O Ports and Expansion Slots of industrial touch panel pc

Extensive I/O ports and expansion slots are crucial features of industrial touch panel PCs, as they facilitate connectivity with various external devices and allow for customization to meet specific application requirements. Here are key considerations for I/O ports and expansion slots:

I/O Ports:

Ethernet Ports:

- Provide multiple Gigabit Ethernet ports for high-speed data communication and network connectivity, essential for industrial networking.

USB Ports:

- Include a variety of USB ports (USB 2.0, USB 3.0, USB Type-C) for connecting peripherals, data storage devices, cameras, and other accessories.

Serial Ports (RS-232/RS-422/RS-485):

- Support legacy industrial equipment and communication protocols, crucial for integration with legacy systems.

HDMI/DisplayPort/VGA Ports:

- Enable connection to external displays or monitors for expanded visual output or dual-screen operation.

Audio Ports:

- Provide audio input/output jacks for applications requiring sound, such as voice alerts or audio monitoring.

GPIO (General Purpose Input/Output):

- Offer digital I/O pins for interfacing with external sensors, switches, and actuators in automation and control applications.

Fieldbus Communication Ports:

- Integrate specialized communication interfaces (e.g., PROFIBUS, Modbus, EtherCAT) for compatibility with industrial fieldbus networks.

CAN Bus Ports:

- Support Controller Area Network (CAN) communication for applications involving vehicle or machinery control systems.

Wireless Connectivity:

- Include Wi-Fi, Bluetooth, or other wireless options for remote communication and IoT integration in industrial environments.

Expansion Slots:

Provide PCIe, Mini-PCIe, or other slots for adding specialized cards, such as GPU cards, additional I/O cards, or fieldbus communication modules.

Expansion Slots:

PCIe Slots:

- Offer high-speed expansion options for adding specialized cards like graphics cards, additional network interfaces, or other high-performance peripherals.

Mini-PCIe Slots:

- Provide smaller form-factor slots for adding expansion cards, such as Wi-Fi modules, GPS receivers, or additional I/O interfaces.

M.2 Slots:

- Support compact M.2 cards for adding storage, wireless connectivity, or other specialized functions.

SIM Card Slots:

- Accommodate SIM cards for cellular connectivity, allowing the touch panel PC to access cellular networks for remote communication.

Custom Expansion Bays:

- Allow for the integration of specialized expansion modules or cards designed for specific industrial applications.

Hot-Swappable Expansion Modules:

- Enable the addition or replacement of expansion modules without shutting down the touch panel PC, minimizing downtime.

GPU Expansion Options:

- Provide dedicated slots or ports for adding graphics processing units (GPUs) for applications that require enhanced graphical processing capabilities.

By offering extensive I/O ports and expansion slots, industrial touch panel PCs can accommodate a wide range of peripherals, interfaces, and expansion cards, making them highly adaptable to diverse industrial applications and environments.

Dust and Water Resistance (IP Rating) of touch panel pcThe Ingress Protection (IP) rating is a crucial specification for touch panel PCs, as it indicates the level of protection they offer against dust and water. The IP rating is typically expressed as "IPXY," where "X" represents the dust resistance level and "Y" represents the water resistance level. Here are common IP ratings and their meanings:

Dust Resistance (First Digit, X): X0 - No special protection against dust. X1 - Protection against solid objects > 50mm (e.g., hands). X2 - Protection against solid objects > 12.5mm (e.g., fingers). X3 - Protection against solid objects > 2.5mm (e.g., tools and wires). X4 - Protection against solid objects > 1.0mm (e.g., small tools and wires). X5 - Dust protected; limited ingress (e.g., no harmful deposit). X6 - Dust tight; complete protection against dust.

Water Resistance (Second Digit, Y): Y0 - No special protection against water. Y1 - Protection against vertically falling drops of water (e.g., condensation). Y2 - Protection against water droplets deflected up to 15 degrees from vertical. Y3 - Protection against sprayed water up to 60 degrees from vertical. Y4 - Protection against splashing water from any direction. Y5 - Protection against water jets (e.g., low-pressure washdown). Y6 - Protection against powerful water jets and heavy seas. Y7 - Protection against the effects of immersion in water up to 1 meter deep for 30 minutes. Y8 - Protection against the effects of continuous submersion in water beyond 1 meter.

For industrial touch panel PCs, a higher IP rating indicates better resistance to dust and water. The specific IP rating needed depends on the environment in which the touch panel PC will be deployed. For example: IP54 - Suitable for most industrial environments with moderate exposure to dust and occasional splashes of water. IP65 - Provides a higher level of protection against dust and can handle low-pressure water jets. Ideal for environments with frequent exposure to water and dust. IP67 - Suitable for harsh environments with exposure to water submersion up to 1 meter for short durations. IP68 - Offers the highest level of protection against dust and water, making it suitable for extreme environments with continuous submersion beyond 1 meter. Selecting the right IP rating ensures that the touch panel PC can withstand the environmental conditions it will encounter in its intended application, helping to prevent damage and ensure reliable operation | Long-Term Reliability of industrial touch panel pcLong-term reliability is a critical consideration for industrial touch panel PCs, as they are often deployed in environments where continuous operation is essential. Here are key factors that contribute to the long-term reliability of these systems: Quality of Components: - Use of high-quality, industrial-grade components that are designed to withstand harsh environmental conditions and provide long-term durability.

Ruggedization and Build Quality: - Incorporation of ruggedized enclosures and construction to protect internal components from physical damage, vibration, and other stressors.

Thermal Management: - Effective thermal solutions, such as heat sinks, fans, or heat pipes, to dissipate heat and prevent overheating, ensuring stable and reliable operation over time.

Environmental Sealing: - Sealing against dust, dirt, moisture, and other environmental factors that could potentially harm internal components.

Extended Temperature Range: - Operation within a wide temperature range, ensuring reliable performance in environments with extreme temperature variations.

Electromagnetic Compatibility (EMC): - Compliance with EMC standards to ensure that the touch panel PC can operate reliably in environments with electromagnetic interference.

Vibration and Shock Resistance: - Design features to absorb or mitigate vibrations and shocks, which are common in industrial environments with heavy machinery.

MTBF (Mean Time Between Failures): - Integration of components with high MTBF ratings, indicating their expected reliability over an extended period.

Redundancy and Failover: - Implementation of redundant components or failover mechanisms to ensure continued operation even in the event of a component failure.

Testing and Quality Assurance: - Rigorous testing during the manufacturing process to identify and address any potential defects or issues before the touch panel PC is deployed.

Firmware and Software Stability: - Use of stable firmware and software, along with regular updates and patches, to address potential vulnerabilities and ensure long-term compatibility with applications.

Long-Term Availability and Support: - Availability of spare parts, extended warranties, and ongoing technical support to address any issues that may arise over the product's lifespan.

Designed for Easy Maintenance: - Accessibility to critical components for servicing, repair, or replacement, minimizing downtime and ensuring continued operation.

Component Lifecycle Management: - Monitoring and management of component lifecycles to anticipate and address potential obsolescence issues.

Compliance with Industry Standards: - Adherence to industry-specific standards and certifications, ensuring that the touch panel PC meets the reliability requirements of the intended application.

By considering these factors, industrial touch panel PCs can be designed and manufactured to provide long-term reliability and performance in demanding industrial environments. This helps minimize downtime, reduce maintenance costs, and ensure uninterrupted operation of critical processes. |

Enhanced Productivity and Efficiency of industrial touch panel pc

Industrial touch panel PCs play a crucial role in enhancing productivity and efficiency in various industrial applications. Here's how they contribute to improved operations: Intuitive Interface: - Touchscreens provide a user-friendly and intuitive interface, reducing the learning curve for operators and enabling faster task execution.

Real-Time Monitoring and Control: - Allows operators to monitor processes and machinery in real-time, enabling immediate adjustments and interventions for optimal performance.

Customized HMI Solutions: - Tailored Human-Machine Interface (HMI) software allows for the creation of interfaces specific to the industrial application, optimizing workflow and data presentation.

Multi-Tasking Capabilities: - Multi-touch screens enable operators to perform multiple tasks simultaneously, increasing efficiency and productivity.

Quick Access to Information: - Touch panel PCs provide immediate access to critical data, reducing the time spent searching for information and enabling faster decision-making.

Remote Monitoring and Control: - Allows for remote access to the touch panel PC, enabling off-site monitoring and control of industrial processes, which can lead to increased operational efficiency.

Reduced Downtime: - Rapid troubleshooting and diagnostics through touch panel PCs help minimize downtime by facilitating quick identification and resolution of issues.

Process Automation: - Integration with PLCs and automation systems allows for seamless control of machinery and processes, reducing the need for manual intervention.

Data Logging and Analysis: - Touch panel PCs can collect and store data for analysis, helping identify trends, inefficiencies, and opportunities for process optimization.

Error Prevention and Alarms: - Touch panel PCs can implement warning systems and alarms to alert operators of potential issues before they escalate, preventing costly errors.

Workflow Optimization: - Customizable interfaces and touch commands can be designed to streamline specific workflows, minimizing unnecessary steps and improving overall efficiency.

Compatibility with Industry Software: - Compatibility with specialized software applications for tasks like CAD, CAM, SCADA, and MES systems enhances productivity by seamlessly integrating with existing workflows.

Paperless Operations: - Electronic data capture and reporting capabilities reduce reliance on manual paper-based processes, saving time and reducing the risk of errors.

Energy Efficiency and Cost Savings: - Touch panel PCs can be integrated with energy management systems to optimize energy usage, leading to cost savings and improved sustainability.

Task Prioritization: - Operators can prioritize tasks through the touch interface, ensuring that critical operations receive the necessary attention.

By leveraging the capabilities of industrial touch panel PCs, businesses can achieve higher levels of productivity, efficiency, and operational effectiveness, ultimately leading to improved competitiveness and profitability |

|

Critical Role in Industry 4.0 and IoT of industrial touch panel pc

Industrial touch panel PCs play a critical role in the advancement of Industry 4.0 (the fourth industrial revolution) and the Internet of Things (IoT). Here's how they contribute:

Integration with IoT Devices:

- Industrial touch panel PCs serve as a central interface for connecting and controlling IoT devices, enabling seamless communication and data exchange.

Real-Time Data Visualization:

- They provide a platform for visualizing real-time data from IoT sensors and devices, allowing for immediate decision-making and process optimization.

Edge Computing Capabilities:

- Touch panel PCs equipped with powerful processors can perform edge computing tasks, enabling data processing and analysis at the source, reducing latency and improving responsiveness.

Gateway Functionality:

- They can act as IoT gateways, aggregating data from multiple sensors and devices, and transmitting it to cloud-based platforms for further analysis and storage.

Interoperability with IoT Protocols:

- Support for various IoT protocols (MQTT, CoAP, OPC UA, etc.) allows touch panel PCs to communicate effectively with diverse IoT devices and platforms.

Remote Monitoring and Control:

- Touch panel PCs enable remote access and control of IoT devices, allowing for monitoring and management from anywhere with an internet connection.

Integration with Industrial Automation:

- They seamlessly integrate with industrial automation systems, facilitating the convergence of operational technology (OT) and information technology (IT) for smarter manufacturing processes.

Predictive Maintenance:

- By analyzing data from IoT sensors, touch panel PCs can help predict equipment failures and schedule maintenance activities, reducing unplanned downtime.

Energy Management and Efficiency:

- They can interface with IoT-enabled energy management systems to optimize energy consumption based on real-time data and demand.

Enhanced Security Measures:

- Touch panel PCs can implement security measures to protect IoT devices and data, including encryption, authentication, and access controls.

Scalability and Flexibility:

- They provide a scalable platform for adding and managing a growing number of IoT devices and sensors as operational needs evolve.

Data Logging and Analysis:

- Touch panel PCs can store and analyze IoT-generated data, providing insights into performance trends, anomalies, and areas for improvement.

Improved Decision Support:

- By providing immediate access to IoT data, touch panel PCs empower operators and decision-makers with the information needed to make informed choices in real-time.

Facilitation of Smart Manufacturing:

- They enable the implementation of smart manufacturing practices, such as just-in-time production, demand-driven manufacturing, and adaptive manufacturing processes.

Compliance with Industry Standards:

- Touch panel PCs ensure that IoT implementations meet industry-specific standards, ensuring interoperability and compliance with regulatory requirements.

Overall, industrial touch panel PCs serve as a crucial bridge between physical operations and the digital world, facilitating the integration of IoT technologies and driving the transformation of industrial processes in the context of Industry 4.0.

Integration with SCADA Systems of industrial touch panel pc

Industrial touch panel PCs play a vital role in the integration with Supervisory Control and Data Acquisition (SCADA) systems. Here's how they facilitate seamless communication and control:

HMI Functionality:

- Touch panel PCs act as the Human-Machine Interface (HMI) for SCADA systems, providing an intuitive and interactive interface for operators to monitor and control industrial processes.

Data Visualization:

- They display real-time data from SCADA systems, allowing operators to view process parameters, alarms, trends, and other critical information in a graphical format.

Control and Command Interface:

- Touch panel PCs enable operators to send commands, set setpoints, and make adjustments to SCADA-controlled processes directly through the touch screen interface.

Alarm Handling:

- They provide visual and audible alarms for abnormal conditions detected by the SCADA system, allowing operators to respond quickly to potential issues.

Trend Analysis:

- Touch panel PCs allow operators to view historical data trends, helping them analyze process performance over time and identify patterns or anomalies.

Data Logging and Reporting:

- They can log data from SCADA systems, allowing for the generation of reports and documentation for regulatory compliance, analysis, and decision-making.

Integration with PLCs:

- Touch panel PCs serve as an intermediary between SCADA systems and Programmable Logic Controllers (PLCs), facilitating communication and control between these critical components.

Remote Access and Control:

- They enable remote access to SCADA systems, allowing operators and supervisors to monitor and control industrial processes from off-site locations.

Redundancy and Failover:

- Touch panel PCs can be configured for redundancy, ensuring uninterrupted operation in case of a SCADA system or network failure.

Protocol Support:

- They are compatible with a variety of communication protocols (e.g., Modbus, OPC UA, DNP3) commonly used in SCADA systems, enabling seamless integration.

Security Measures:

- Touch panel PCs implement security features such as user authentication, encryption, and access controls to protect sensitive data and control commands exchanged with SCADA systems.

High-Performance Processing:

- Industrial-grade touch panel PCs with powerful processors can handle the data processing demands of SCADA systems, ensuring smooth and responsive operation.

Customizable Interfaces:

- They allow for the creation of customized SCADA HMI screens to suit specific process requirements, optimizing operator workflow and data presentation.

Compatibility with Legacy Systems:

- Touch panel PCs can bridge the gap between older legacy systems and modern SCADA platforms, ensuring seamless communication and integration.

By serving as the interface between operators and SCADA systems, industrial touch panel PCs enhance the effectiveness of process monitoring and control, leading to improved operational efficiency, reduced downtime, and enhanced overall productivity.

Industry-Specific Applications of industrial touch panel pc

Industrial touch panel PCs find application in various industries due to their ruggedness, versatility, and ability to interface with specialized equipment. Here are industry-specific applications:

Manufacturing and Automation:

- Control and monitoring of assembly lines, robotics, CNC machines, and other automated processes for efficient production.

Food and Beverage Processing:

- Recipe management, batch control, and process monitoring in food and beverage production facilities to ensure quality and compliance.

Pharmaceutical and Life Sciences:

- Cleanroom environments, batch tracking, and process control in pharmaceutical manufacturing for compliance with regulatory standards.

Oil and Gas:

- Monitoring of drilling operations, control of offshore platforms, and management of processing facilities for safe and efficient energy production.

Chemical and Petrochemical:

- Process control, data logging, and safety monitoring in chemical processing plants to ensure accurate and secure operations.

Water and Wastewater Treatment:

- SCADA systems, monitoring of pumps and valves, and data logging for efficient water treatment and distribution.

Utilities and Energy Management:

- Monitoring and control of electrical substations, renewable energy systems, and power distribution for reliable energy supply.

Transportation and Logistics:

- Control of traffic management systems, tracking and tracing of shipments, and management of logistics operations for efficient transportation.

Healthcare and Medical Devices:

- Integration with medical equipment, patient monitoring systems, and healthcare information systems for improved patient care.

Agriculture and Farming:

- Monitoring of agricultural machinery, control of irrigation systems, and data analysis for precision farming and increased crop yield.

Mining and Minerals Processing:

- Control and automation of mining equipment, monitoring of processing plants, and ensuring safety in mining operations.

Building Automation and HVAC:

- Integration with building management systems for climate control, lighting, and security in commercial and industrial facilities.

Aerospace and Defense:

- Control and monitoring of aircraft systems, navigation, and defense equipment for safe and efficient aerospace operations.

Environmental Monitoring:

- Data collection and analysis for air quality, water quality, and environmental conditions to support environmental protection efforts.

Retail and Point of Sale (POS):

- Touch panel PCs are used in retail environments for point-of-sale operations, inventory management, and customer service kiosks.

Entertainment and Hospitality:

- Integration with entertainment systems, self-service kiosks, and customer service applications in the hospitality industry.

Education and Training:

- Interactive learning environments, digital whiteboards, and educational applications in classrooms and training centers.

These are just a few examples, and the versatility of industrial touch panel PCs allows them to be adapted for a wide range of specialized applications in various industries. Their ruggedness, reliability, and ability to interface with specialized equipment make them invaluable tools for optimizing processes and operations.

FAQS about industrial touch panel pc

What is an industrial touch panel PC and how does it differ from a regular PC?

- An industrial touch panel PC is a specialized computing device designed for use in industrial environments. It differs from a regular PC in that it is built to withstand harsh conditions, featuring rugged construction, extended temperature range, and often includes features like dust and water resistance.

How does an industrial touch panel PC ensure reliability and durability in industrial environments?

- Industrial touch panel PCs ensure reliability and durability through the use of high-quality components, robust construction, and adherence to strict manufacturing standards. They are built to withstand factors like extreme temperatures, vibrations, and exposure to dust or moisture.

Which industrial automation systems can an industrial touch panel PC integrate with?

- Industrial touch panel PCs can integrate with a wide range of industrial automation systems, including PLCs (Programmable Logic Controllers), SCADA (Supervisory Control and Data Acquisition) systems, DCS (Distributed Control Systems), and more.

What specific design features help an industrial touch panel PC resist interference in industrial settings?

- Industrial touch panel PCs are designed with features like electromagnetic interference (EMI) shielding, grounded metal enclosures, and robust electrical components to minimize the impact of electromagnetic interference on their operation.

Which operating systems are typically supported by industrial touch panel PCs?

- Industrial touch panel PCs typically support a variety of operating systems, including various versions of Windows, Linux, and sometimes specialized industrial operating systems tailored for specific applications.

What types of touch screen technologies are commonly used in industrial touch panel PCs?

- Common touch screen technologies used in industrial touch panel PCs include resistive, capacitive, and sometimes specialized technologies like infrared or optical touch.

Can an industrial touch panel PC be used in hazardous environments?

- Yes, some industrial touch panel PCs are designed to be intrinsically safe and can be used in hazardous environments. They may have certifications like ATEX or IECEx to ensure compliance with safety standards.

How does an industrial touch panel PC handle power fluctuations and surges?

- Industrial touch panel PCs often incorporate features like surge protection, power filtering, and in some cases, even have built-in uninterruptible power supply (UPS) options to ensure stable operation in the event of power fluctuations.

What is the typical lifespan of an industrial touch panel PC?

- The typical lifespan of an industrial touch panel PC can vary depending on usage, environmental conditions, and quality of components. However, they are generally designed for long-term use and often exceed 5 years.

Is it possible to customize an industrial touch panel PC to meet specific industrial application requirements?

- Yes, many industrial touch panel PCs offer customization options, including screen size, processing power, I/O ports, and additional features to meet the specific requirements of different industrial applications.