Technology of industrial monitorIndustrial monitors use various technologies to meet the demands of harsh environments and specific industry requirements. Here are some of the key technologies used in industrial monitors: LCD (Liquid Crystal Display): - Description: LCD technology uses liquid crystals to manipulate light and create images on a flat panel.

- Advantages: Energy-efficient, available in various sizes and resolutions, and offer good color reproduction.

- Applications: LCD monitors are widely used in a range of industrial applications due to their versatility and cost-effectiveness.

OLED (Organic Light Emitting Diode): - Description: OLED displays use organic compounds that emit light when an electric current is applied. This technology offers high contrast ratios, fast response times, and vibrant colors.

- Advantages: Superior contrast and color reproduction, wider viewing angles, and faster response times compared to traditional LCDs.

- Applications: OLED monitors are used in applications where high-quality visuals and color accuracy are crucial, such as medical imaging and entertainment.

LED Backlighting: - Description: LED (Light Emitting Diode) backlighting is used in conjunction with LCD panels to provide illumination. It can be edge-lit or direct-lit.

- Advantages: Provides bright and energy-efficient illumination, allowing for thinner monitor designs.

- Applications: LED backlighting is used in various types of industrial monitors to ensure high brightness and energy efficiency.

Resistive Touchscreen: - Description: Resistive touchscreens consist of multiple layers, with a flexible top layer that responds to pressure, allowing touch input.

- Advantages: Cost-effective, durable, and can be operated with gloves or stylus.

- Applications: Commonly used in industrial settings where reliability and durability are crucial, such as manufacturing and automation.

Capacitive Touchscreen: - Description: Capacitive touchscreens use the conductive properties of the human body to detect touch input. They are made of a glass panel with a capacitive sensor grid.

- Advantages: Offer higher touch sensitivity and multi-touch capabilities, making them suitable for more interactive applications.

- Applications: Used in environments where precise and responsive touch input is required, such as HMI interfaces in automation.

Projected Capacitive Touchscreen: - Description: A type of capacitive touchscreen where the sensor array is embedded in the display glass. It allows for multi-touch and gesture recognition.

- Advantages: Highly responsive, durable, and supports advanced touch gestures.

- Applications: Commonly used in applications where high levels of interactivity and precision are needed, such as kiosks and public displays.

Optical Bonding: - Description: Optical bonding involves laminating a protective layer directly onto the display to reduce reflection and improve contrast.

- Advantages: Enhances visibility in high-glare environments and increases ruggedness.

- Applications: Used in outdoor and high-ambient-light environments where visibility is critical, such as marine displays and ruggedized outdoor monitors.

Anti-Glare Coatings: - Description: Anti-glare coatings are applied to the surface of the display to reduce reflections and minimize glare from ambient light sources.

- Advantages: Improve visibility in well-lit environments and reduce eye strain.

- Applications: Widely used in monitors deployed in environments with high levels of ambient light.

These technologies can be combined and customized to meet the specific requirements of various industrial applications, ensuring that the monitors are rugged, reliable, and suitable for their intended environments.

| Process of industrial monitorThe process of manufacturing an industrial monitor involves several steps. Below is an overview of the typical stages involved: Design and Planning: - The process starts with the design phase where engineers and designers create the specifications and blueprints for the industrial monitor. This includes selecting the appropriate screen technology, touch interface (if applicable), and other features based on the intended application.

Component Procurement: - Once the design is finalized, the manufacturer procures the necessary components. This includes the LCD or OLED panel, touchscreens (if required), backlighting, controller boards, housing materials, and other electronic components.

Panel Assembly: - The LCD or OLED panel is assembled, which involves attaching the backlighting, touchscreen (if applicable), and any other necessary components. This process may vary depending on the specific technology used.

Electronics Integration: - The electronic components, including the controller board, power supply, and interface ports, are integrated into the monitor. This stage also involves connecting the panel assembly to the electronics.

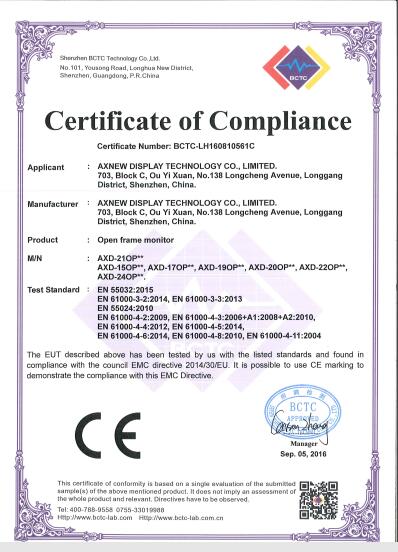

Testing and Quality Control: - The assembled monitor undergoes extensive testing to ensure it meets specified performance criteria. This includes checking for dead pixels, verifying touch functionality (if applicable), and assessing color accuracy. Quality control measures are taken to identify and rectify any defects or deviations from specifications.

Enclosure Manufacturing: - The housing or enclosure of the industrial monitor is fabricated. This may involve using materials such as metal, plastic, or a combination of both, depending on the desired level of ruggedness and environmental protection.

Assembly and Integration: - The electronic components and panel assembly are integrated into the enclosure. This stage also includes mounting brackets, cable management, and any additional features specific to the design.

Final Testing and Calibration: - The fully assembled monitor undergoes final testing to ensure all components are functioning correctly. This includes calibrating touchscreens, if present, to ensure accurate touch input.

Software Installation (if applicable): - If the monitor requires specific software or firmware, it is installed during this phase. This may include drivers, firmware updates, or specialized applications tailored to the monitor's intended use.

Packaging and Labeling: - The finished industrial monitors are carefully packaged to protect them during transit. Labels, serial numbers, and other relevant information are applied.

Shipping and Distribution: - The monitors are prepared for shipping and sent to distributors, resellers, or directly to end-users depending on the manufacturer's distribution model.

Installation and Commissioning: - Upon arrival at the end-user's location, the monitors are installed and commissioned according to the specific application. This may involve mounting, connecting to power sources and data interfaces, and configuring settings.

It's important to note that the specific processes and technologies used may vary depending on the manufacturer and the type of industrial monitor being produced. Additionally, quality assurance and compliance with industry standards play a crucial role throughout the entire manufacturing process. |