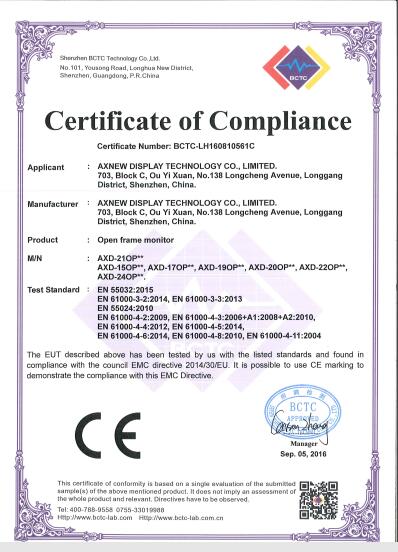

Technology of rugged industrial monitorThe technology behind rugged industrial monitors involves several key aspects designed to ensure their durability, reliability, and functionality in harsh environments. Here are some of the key technological features: Ruggedized Materials: Rugged industrial monitors are constructed using robust materials such as reinforced metal or aluminum frames, impact-resistant glass, and durable components to withstand physical stresses and environmental conditions. Environmental Sealing: Critical components of the monitor, including the display panel, touchscreens, and internal electronics, are sealed to protect against dust, moisture, and other environmental elements. This is often indicated by an IP (Ingress Protection) rating. Advanced Touchscreen Technology: If equipped with a touchscreen, rugged monitors use specialized touchscreen technologies like resistive, capacitive, or SAW (Surface Acoustic Wave) to provide reliable and responsive touch input in various conditions. High-Brightness Displays: Rugged monitors often feature high-brightness screens to ensure clear visibility even in environments with high ambient light levels, such as outdoor settings or areas with strong industrial lighting. Anti-Glare/Anti-Reflective Coatings: Coatings on the screen help reduce glare and reflections, further enhancing visibility in bright conditions. Impact Resistance: The design of rugged monitors includes features to absorb shocks and vibrations, protecting internal components from damage due to physical impacts. Wide Temperature Range Components: Industrial-grade components and electronics are selected to operate within a broad temperature range, ensuring functionality in extreme hot or cold environments. EMI/RFI Shielding: Rugged monitors are often equipped with shielding to protect against electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring stable operation in electrically noisy environments. Long Lifespan Components: The internal components are selected for their longevity and reliability, reducing the need for frequent replacements and minimizing downtime. Customization Options: Manufacturers often offer customization options to tailor the monitor's features, such as screen size, touchscreen technology, connectors, and additional functionalities, to specific industry requirements. Compliance with Industry Standards: Rugged monitors are designed to meet specific industry standards, ensuring compatibility with existing systems and equipment.

These technological features collectively contribute to the ruggedness and resilience of industrial monitors, making them suitable for use in challenging and demanding environments. | Process of rugged industrial monitorThe process of manufacturing a rugged industrial monitor involves several stages, each crucial for ensuring its durability, functionality, and reliability in harsh environments. Here's a simplified overview of the process: Design and Planning: - Engineers and designers collaborate to create a blueprint for the rugged monitor. This includes selecting materials, components, and specifying the features it will have.

Component Selection: - High-quality, durable components are chosen, including display panels, touchscreens (if applicable), internal electronics, connectors, and protective enclosures.

Assembly of Electronic Components: - Skilled technicians assemble the electronic components onto the monitor's circuit board. This includes attaching the display panel, touchscreen (if applicable), control board, and other internal components.

Enclosure and Housing Fabrication: - The rugged housing or enclosure is fabricated from robust materials like reinforced metal or aluminum to provide physical protection.

Sealing and Gasketing: - Specialized seals and gaskets are installed to provide environmental protection. This ensures that the monitor is resistant to dust, moisture, and other potentially damaging elements.

Integration of Touchscreen Technology: - If the monitor includes a touchscreen, the chosen touchscreen technology (e.g., resistive, capacitive) is integrated into the display.

Testing and Quality Control: - The monitor undergoes rigorous testing to verify its functionality and durability. This includes checks for visual defects, touchscreen responsiveness (if applicable), and performance under varying conditions.

Installation of Input/Output Connectors: - Input and output connectors are installed to facilitate connections with external devices and systems.

OSD Control Integration: - On-Screen Display (OSD) controls, if included, are integrated into the monitor. This allows users to adjust settings directly on the monitor.

Final Assembly and Inspection: - All components are assembled, and the monitor undergoes a final inspection to ensure that everything is in place and functioning as intended.

Customization (Optional): - If specified by the customer, the monitor may undergo additional customization to meet specific industry or application requirements.

Packaging and Shipping: - The rugged industrial monitor is carefully packaged to protect it during transit. It is then shipped to its destination.

Please note that this is a simplified overview, and the actual manufacturing process may involve additional steps and quality checks, depending on the specific manufacturer and model of the rugged industrial monitor.

|